Unlocking Precision for Non-Round Forms

Ever wondered how those perfectly formed hex holes, splines, or intricate polygonal drives are created with such precision and efficiency in metal components? While traditional machining often focuses on round geometries, the demand for non-round features in critical parts is ever-present. This is where rotary broaching, also known as wobble broaching, steps in as a specialized and remarkably efficient machining process. It allows manufacturers to produce precise internal and external polygonal forms directly on standard CNC machines.

Unlike conventional linear broaching, which typically demands a dedicated, powerful machine and can be a slower, multi-step process, rotary broaching offers a distinct advantage. It’s a single-pass operation performed quickly and effectively on common CNC lathes, turning centers, and even milling machines, making it a versatile and cost-effective solution for a myriad of industries. This article will demystify the ingenious mechanics of rotary broaching, explore its compelling advantages, highlight its common applications, and provide practical considerations for its implementation.

The Ingenious Mechanics: How it Works

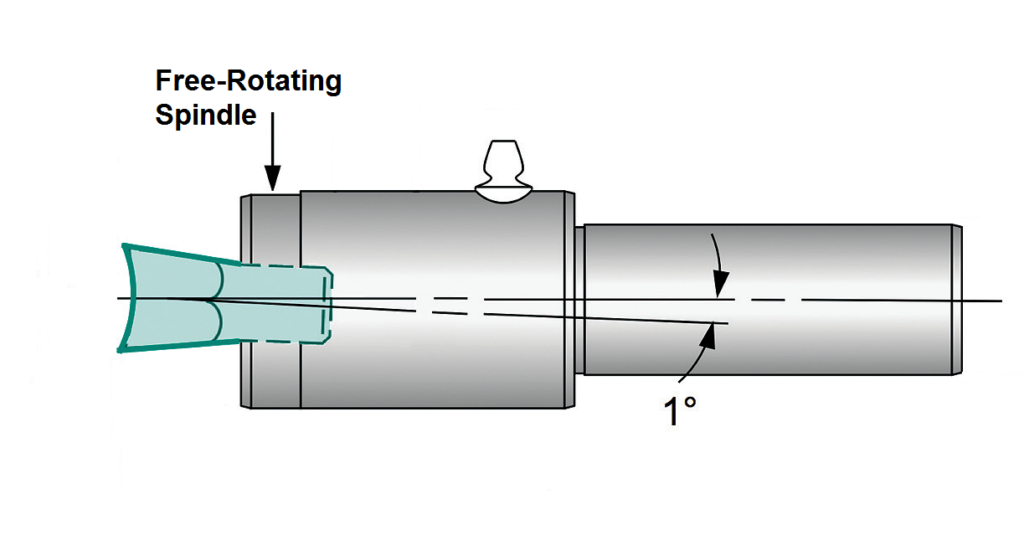

The core principle behind rotary broaching is deceptively simple yet highly effective: the “wobble” effect. This is achieved by setting the rotary broach tool at a slight angular offset (typically around 1 degree) relative to the workpiece’s centerline. As the broach tool is fed into the rotating workpiece (on a lathe) or rotated around the stationary workpiece (on a mill), this precise angular misalignment creates a unique cutting action.

Instead of all cutting edges engaging simultaneously, the angle ensures that only a small portion of the broach’s cutting edge makes contact with the material at any given moment. Imagine a coin spinning rapidly on a table, touching only a sliver of its edge. This creates a continuous shearing or shaving action, incrementally removing material to form the desired shape. This single-point cutting action dramatically reduces the cutting force (thrust) required, making the process achievable on less rigid machines.

The rotary broach holder typically contains a live spindle that allows the broach tool to freely rotate, synchronously spinning with the workpiece when used on a lathe. This synchronized rotation, combined with the precise angular offset, defines the unique and efficient cutting motion of rotary broaching.

Why Choose Rotary Broaching? Key Advantages

Adopting rotary broaching offers a compelling array of benefits that directly impact manufacturing efficiency, part quality, and overall cost-effectiveness:

- Single-Pass Efficiency: This “done-in-one” capability means complex polygonal forms are created in a single pass, often in mere seconds. This drastically reduces cycle times and eliminates the need for multiple setups or tooling changes.

- Superior Precision & Surface Finish: The controlled shearing action and reduced cutting forces allow for exceptional precision, holding tolerances down to 0.0005 inches (0.0127 mm). It also yields excellent surface finishes, often eliminating secondary finishing operations.

- Versatility in Applications:

- Internal & External Forms: Equally adept at creating both (e.g., internal hexes in fasteners, external splines on shafts).

- Blind Holes: Unlike conventional broaching, it can effectively create forms in blind holes, provided adequate chip relief space is designed.

- Machine Compatibility: It runs on standard CNC lathes, turning centers, machining centers, and Swiss-type machines, removing the need for dedicated, expensive broaching equipment.

- Reduced Tool Wear & Increased Tool Life: Lower cutting forces and the shearing action minimize stress on the tool, leading to longer tool life and fewer changes.

- Cost-Effectiveness: Streamlining the process into a single operation using existing machine tools often eliminates expensive secondary operations like EDM, shaping, or grinding, resulting in substantial overall cost reductions per part.

- Wide Material Compatibility: Effective across a broad spectrum of machinable materials, including aluminum, brass, steels (carbon, stainless), titanium, plastics, and even hardened materials up to approximately 50 HRC.

Common Applications and Industries

Rotary broaching’s ability to create precise non-round features in a single pass makes it indispensable across numerous industries:

- Specific Forms: Hexagons, squares, Torx/Hexalobe, splines, serrations, Double D’s, keyways, and custom polygons.

- Industry Examples:

- Aerospace: High-precision fasteners and complex fluid connectors.

- Medical: Orthopedic implants (e.g., bone screws with hex drives), surgical instruments, and dental components.

- Automotive: Specialty fasteners, internal drive mechanisms, and various engine/transmission components.

- Fastener Industry: Mass production of nuts, bolts, screws, and standoffs with internal drives.

- Fluid Power/Plumbing: Connectors, valve bodies, and fittings requiring specific internal shapes.

Practical Considerations and Setup Tips

While rotary broaching simplifies the overall process, proper setup and understanding a few key considerations are vital for optimal results:

- Pilot Hole Preparation (for Internal Broaching): A pre-drilled or bored pilot hole is essential. It should be slightly oversized (e.g., 0.001″ – 0.003″ larger than the across-flats dimension of the broach) to allow for chip clearance. Crucially, the pilot hole must be deeper than the desired broached depth to provide “chip relief” space at the bottom, preventing hydraulic lock and chip damage. A lead chamfer at the hole’s entry also aids tool guidance and longevity.

- Machine Rigidity & Setup: Even with reduced thrust forces, a stable and rigid machine setup is paramount for achieving the highest precision and prolonging tool life. Ensure proper tool holding and workpiece fixturing.

- Speeds and Feeds: Start with conservative speeds (RPM) and feed rates. Once stable, the feed rate can often be increased significantly. Optimal parameters depend on the material, tool, and desired finish.

- Coolant & Chip Management: Effective coolant application is critical to lubricate cutting, dissipate heat, and flush chips away. Proper chip evacuation prevents recutting and ensures a clean, accurate form.

- Limitations: Rotary broaching is generally best suited for smaller forms (typically under 2 inches in diameter) and shallower depths compared to linear broaching. Its efficiency shines when applied within these parameters.

Conclusion

Rotary broaching stands as a powerful and efficient solution for creating precise non-round forms in modern manufacturing. Its unique wobble mechanism, coupled with its ability to be performed on standard CNC equipment, delivers significant advantages in speed, accuracy, versatility, and cost-effectiveness. By understanding its mechanics and practical considerations, manufacturers can leverage rotary broaching to simplify complex machining challenges, reduce production costs, and expand their design possibilities.

At HIRUNG, we are at the forefront of providing innovative machining solutions. Our robust and precise CNC machines are perfectly suited to seamlessly integrate advanced processes like rotary broaching, ensuring your operations achieve maximum efficiency and superior quality. We empower manufacturers to push the boundaries of what’s possible in precision engineering.