p>In the world of modern manufacturing, precision, efficiency, and repeatability are paramount. At the heart of this revolution is the CNC milling machine, a cornerstone technology that has transformed how we create everything from simple components to complex, mission-critical parts. As a leading manufacturer of high-performance CNC machine tools, we at Hirung want to share our expert insights into this essential technology.

This comprehensive guide will explain what a CNC milling machine is, how it works, its key components, and the incredible advantages it brings to industries worldwide.

1. What Exactly is CNC Milling?

A CNC (Computer Numerical Control) milling machine is an automated manufacturing tool that uses computer-guided controls and rotating multi-point cutting tools to progressively remove material from a workpiece, shaping it into a desired part or product. It is a form of subtractive manufacturing, meaning it creates the final shape by cutting material away from a solid block, also known as a blank or workpiece.

Unlike manual milling, which requires an operator to continuously control the machine’s motion and cuts, CNC milling relies on a computer program. This program, typically G-code, dictates the tool’s path, speed, feed rate, and all other variables with extreme precision. The result is the ability to produce highly accurate and identical parts, time after time.

2. The CNC Milling Process: From Digital Design to Physical Part

The journey from a concept to a finished milled part follows a precise digital workflow. As experts in building the machines that power this process, we know every step is critical for a high-quality outcome.

- Design (CAD): The process begins with a 2D or 3D digital model created using Computer-Aided Design (CAD) software. This file is the blueprint for the final part.

- Programming (CAM): The CAD file is imported into Computer-Aided Manufacturing (CAM) software. Here, a programmer plans the machining strategy, including which tools to use, the toolpaths, and the cutting speeds and feeds. The CAM software then exports this strategy as a set of machine-readable instructions called G-code.

- Machine Setup: An operator securely fixes the workpiece onto the machine’s worktable and loads the necessary cutting tools into the machine’s tool holder or automatic tool changer.

- Execution (Machining): The operator loads the G-code program into the CNC machine’s controller. Once the program starts, the machine takes over, automatically executing the programmed commands. The spindle spins the cutting tool, and the machine’s axes move the tool and/or the workpiece to perform the cuts, shaping the material into the final part with minimal human intervention.

3. Anatomy of a CNC Milling Machine: Key Components

A CNC milling machine is a sophisticated piece of equipment. Understanding its core components helps appreciate its capability for precision and power.

- Controller: The “brain” of the machine. It reads the G-code and translates it into electrical signals that direct the motors to move the machine’s axes and control the spindle.

- Spindle: The component that holds and rotates the cutting tool at high speeds. The quality and power of the spindle are critical for cutting performance and surface finish.

- Cutting Tool: The tool that performs the material removal. Tools come in countless shapes and sizes (e.g., end mills, face mills, drills), each designed for a specific type of cut.

- Worktable: The surface where the workpiece is mounted. The table moves along the X and Y axes in most common machine configurations.

- Axis System: These are the linear and/or rotary guides that allow the tool and workpiece to move relative to each other. A standard machine has at least three linear axes (X, Y, and Z).

4. Exploring the Types of CNC Milling Machines

CNC milling machines are not one-size-fits-all. They are designed for different applications, part sizes, and complexities. At Hirung, we specialize in a comprehensive range to meet these diverse needs.

Vertical Machining Centers (VMC)

In a VMC, the spindle is oriented vertically. These are the most common type of CNC mill, prized for their versatility and ease of use. They are ideal for single-sided machining operations on flat parts, such as creating pockets, slots, and drilled holes. Hirung’s VMC series is renowned for its stability and precision in these applications.

Horizontal Machining Centers (HMC)

In an HMC, the spindle is oriented horizontally. These machines are often equipped with a pallet-changing system, allowing one part to be machined while another is being set up. They excel at machining multiple sides of a part in a single setup, improving efficiency and accuracy for more complex, cube-shaped components.

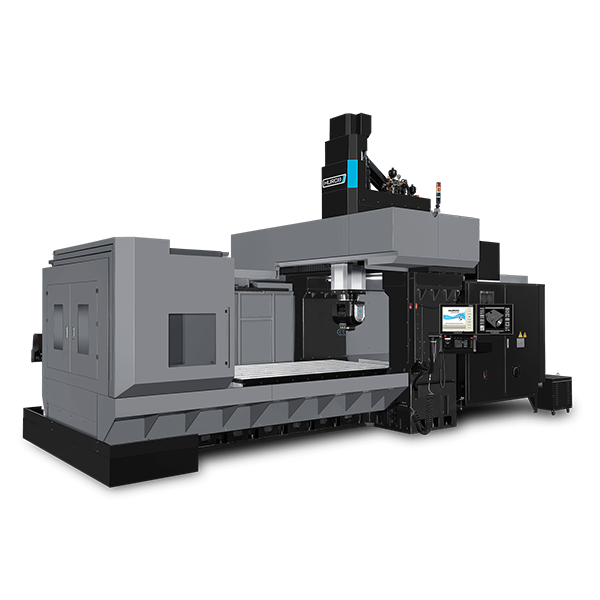

Gantry Machining Centers

For very large and heavy workpieces, such as molds for the automotive or aerospace industries, a gantry machine is the solution. The machine’s bridge-like structure (gantry) moves over a stationary worktable, providing the rigidity needed to machine massive parts with high precision.

Multi-Axis Milling (4-Axis and 5-Axis)

While standard machines operate on 3 axes (X, Y, Z), more advanced machines add rotational axes. A 4-axis machine adds one rotational axis, and a 5-axis machine adds two. This allows the cutting tool to approach the workpiece from any angle, making it possible to create incredibly complex geometries in a single setup, which drastically reduces setup time and improves accuracy.

5. Common CNC Milling Operations

A single CNC mill can perform a wide array of cutting operations, including:

-

- Face Milling: Creating a flat, smooth surface on the face of the workpiece.

- Pocket Milling: Removing material to create a hollow pocket or cavity within the part.

– Slot Milling: Cutting narrow grooves or channels into the part.

- Drilling: Creating round holes.

- Boring: Enlarging an existing hole with high precision.

- Tapping: Cutting internal threads into a hole.

6. Materials Compatible with CNC Milling

One of the great strengths of CNC milling is its ability to work with a vast range of materials, provided the machine is rigid and powerful enough. Hirung machines are engineered for this versatility.

- Metals: Aluminum, Steel, Stainless Steel, Titanium, Brass, Copper

- Plastics: ABS, Polycarbonate, Nylon, PEEK

- Composites: Carbon Fiber, Fiberglass

- Wood and more

7. The Unmatched Advantages of CNC Milling

Adopting CNC milling technology offers transformative benefits for any manufacturing operation.

Unwavering Precision and Repeatability

Computer control eliminates human error, allowing for tolerances as tight as a few microns. Every part produced from the same program will be virtually identical, ensuring consistent quality.

Complex Geometries Made Simple

With multi-axis machines, shapes that would be impossible or prohibitively expensive to create manually can be machined with ease.

Enhanced Production Speed and Efficiency

CNC machines can run 24/7 with minimal supervision. Optimized toolpaths and high-speed cutting capabilities drastically reduce cycle times compared to manual methods.

Automation and Reduced Labor Costs

While skilled programmers and operators are essential, a single operator can often oversee multiple machines, increasing labor productivity and reducing costs.

8. How to Choose the Right CNC Milling Machine

Selecting the correct machine is a critical investment. The decision depends on several key factors:

- Workpiece Size and Weight: The machine’s travel (X, Y, Z dimensions) and table load capacity must accommodate your parts.

- Part Complexity: Simple, 2.5D parts may only require a 3-axis VMC, while highly contoured parts will necessitate a 5-axis machine.

- Material Type: Harder materials like titanium require a more rigid and powerful machine than softer materials like aluminum.

- Production Volume: High-volume production may benefit from features like automatic pallet changers found on HMCs to minimize downtime.

9. Partner with Hirung for Your Manufacturing Excellence

The CNC milling machine is more than just equipment; it is the engine of modern production. Its ability to transform digital designs into precise, high-quality physical parts has made it an indispensable tool across every major industry, from aerospace and automotive to medical and consumer electronics.

As a dedicated CNC machine tool manufacturer since 2003, Hirung is committed to pushing the boundaries of what these machines can do. We provide not just machines, but complete manufacturing solutions built on a foundation of high quality, high precision, and high efficiency. Our professional R&D team and strict quality control ensure every machine we build is a reliable asset for your business.

Whether you are just beginning your journey with CNC technology or are looking to upgrade your capabilities with advanced VMCs, HMCs, or gantry systems, our team is here to provide expert consultation and support. Partner with Hirung to achieve manufacturing excellence.