Yes, 6-axis CNC machines absolutely exist, but they are highly specialized, often misunderstood, and far less common than their 3, 4, and 5-axis counterparts. The core of the confusion lies in the definition: a true 6-axis CNC machine features six axes that can all move simultaneously and in coordination (interpolation) to machine a workpiece from incredibly complex angles. This is distinct from more common “5+1” configurations, where a 5-axis machine has an additional, non-interpolated sixth axis for automated tasks like part feeding or pallet changing. As a leading manufacturer of advanced CNC solutions, we at Hirung believe it’s crucial to clarify these distinctions to help you understand the true capabilities and applications of this cutting-edge technology.

What Exactly is a 6-Axis CNC Machine?

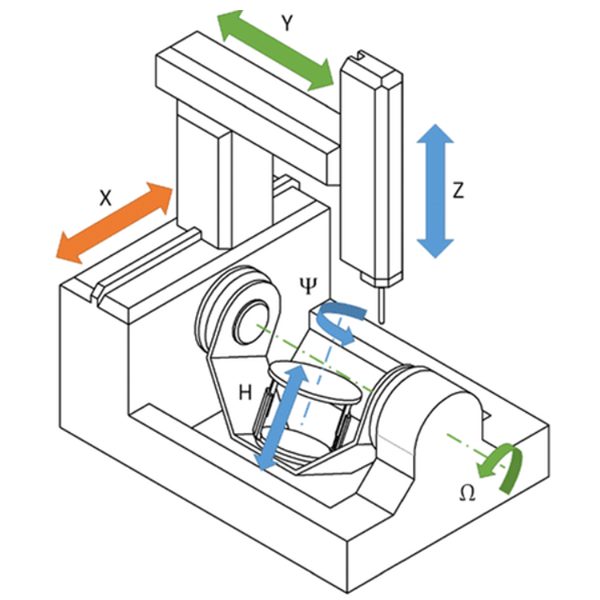

To understand what a 6-axis machine is, we must first be clear about how we define the axes of motion in CNC machining. A standard machine operates on three linear axes: X (left-right), Y (front-back), and Z (up-down). Adding rotational capabilities creates more advanced machines. A 5-axis machine adds two of three possible rotational axes (A, which rotates around X; B, which rotates around Y; and C, which rotates around Z) to the three linear axes. A 6-axis machine takes this one step further, incorporating all three linear and all three rotational axes, all working in perfect harmony.

Defining the Axes: Beyond the Standard 5-Axis Configuration

In the world of CNC, precision is defined by control over movement. The axes represent the directions in which the cutting tool or the workpiece can move. Let’s break it down:

- 3-Axis (X, Y, Z): The foundation of all CNC. The tool moves up-and-down, left-and-right, and forward-and-back. This is ideal for simple parts like blocks, plates, and basic molds.

- 4-Axis (X, Y, Z + A): Adds a single rotational axis, typically the A-axis, allowing the workpiece to be rotated. This is useful for engraving on cylindrical parts or milling features on multiple sides of a part in a single setup.

- 5-Axis (X, Y, Z + A, C or B, C): Introduces two rotational axes. This is a massive leap in capability, allowing the tool to approach the workpiece from a virtually infinite number of angles. It enables the machining of highly complex surfaces, such as turbine blades or custom automotive parts, in a single clamping. This is the technology behind advanced machines like Hirung’s VMC and Gantry series.

- 6-Axis (X, Y, Z + A, B, C): The pinnacle of motion control. By having three linear and three rotational axes all capable of simultaneous, interpolated movement, the machine gains unparalleled freedom. The cutting tool can not only approach the workpiece from any angle (like a 5-axis) but can also manipulate its orientation along that path in ways previously impossible.

“True” 6-Axis vs. “5+1” Axis: A Critical Distinction

This is where most of the market confusion originates. Many machine tool manufacturers will advertise a “6-axis” machine that is, in reality, a 5+1 axis system. While technically having six controllable axes, the crucial difference is that the sixth axis does not interpolate simultaneously with the other five during the cutting process. It operates independently for an auxiliary function. Understanding this difference is vital for making an informed investment.

| Feature | True 6-Axis CNC Machine | “5+1” Axis CNC Machine |

|---|---|---|

| Core Function | All six axes (X,Y,Z,A,B,C) move simultaneously and are fully interpolated for complex toolpaths. | Five axes (X,Y,Z + two rotational) are interpolated for cutting. The 6th axis performs a separate function. |

| The 6th Axis | An integral part of the cutting process, providing additional tool orientation or workpiece manipulation. | An auxiliary axis for automation, such as a pallet changer, bar feeder, or part flipper. |

| Programming | Extremely complex; requires specialized CAM software and highly skilled programmers. | Programmed as a 5-axis machine, with the 6th axis controlled by simple M-codes for its automated task. |

| Primary Use Case | Machining hyper-complex parts that are impossible on a 5-axis machine. | Increasing the productivity and automation of a 5-axis machining process (“lights-out” manufacturing). |

How a True 6th Axis Achieves Synchronized Motion

The magic of a true 6-axis machine is in its control system and kinematics. The machine’s controller must be powerful enough to calculate the complex differential movements required to keep all six axes in perfect sync. A common configuration for a true 6-axis machine involves a specialized articulated head, sometimes called a “wrist,” on the spindle. While the machine table provides two rotational axes (like A and C), this wrist provides the third (B-axis). This allows the tool’s cutting edge to remain perfectly perpendicular or at a specific lead/lag angle to a highly contoured surface, even while navigating sharp directional changes. This eliminates the need to stop and reorient, leading to superior surface finishes and the ability to machine undercuts and internal features that would otherwise be inaccessible.

The Evolution of Machining: Why Did We Move Beyond 5-Axis?

For decades, 5-axis machining has been the gold standard for complex manufacturing. It revolutionized industries by enabling “single setup” or “done-in-one” machining, drastically reducing setup times and improving accuracy by eliminating the need to re-fixture a part. However, as ambitions in design and engineering grew, certain applications began to bump up against the inherent limitations of even this advanced technology, paving the way for the development of 6-axis solutions.

The Limitations of 5-Axis Machining

While incredibly capable, 5-axis machines can encounter challenges with certain geometries. One key limitation is tool ‘lock’ or singularity, where the machine’s rotational axes reach their physical limits and cannot complete a desired toolpath without a complex and inefficient reorientation. This can happen when machining deep pockets with curved walls or complex internal features. Another challenge is maintaining optimal tool pressure and cutting angle on exceptionally contoured surfaces, such as those found on blisks (bladed disks) in jet engines. A 5-axis machine can do the job, but it may require slower feed rates or less-than-ideal tool angles, potentially compromising surface finish or tool life.

The Complex Geometries Demanding a 6th Axis

The need for a sixth axis arose from parts with features that are essentially “hidden” from a 5-axis toolpath. Imagine carving the inside of a twisted tube or machining a cooling channel that spirals within a solid block of metal. A 6-axis machine can simultaneously move the workpiece and articulate the cutting tool in a way that keeps the tool perfectly engaged with the surface, even as it navigates these “impossible” internal paths. This capability is driven by industries where performance is paramount and component designs are pushed to the absolute limits of physics, such as aerospace propulsion and high-performance energy generation.

6-Axis CNC vs. 5-Axis CNC: A Head-to-Head Comparison

Choosing between a 5-axis and 6-axis machine is a decision driven by necessity, not just a desire for more axes. The increase in capability comes with significant trade-offs in complexity and cost. As manufacturers of high-performance 5-axis CNCs, we at Hirung often guide customers through this decision-making process.

Degrees of Freedom and Tool Path Control

The primary advantage of 6-axis machining is its superior *degrees of freedom*. This translates into unparalleled tool path control. While a 5-axis machine can point the tool in almost any direction, a 6-axis machine can do that while also ‘rolling’ the tool along its own axis in a controlled manner relative to the workpiece. This allows it to maintain a constant cutting angle on a surface that is both curving and twisting, reducing chatter, improving surface quality, and enabling the use of shorter, more rigid tools for higher precision and faster material removal.

Programming Complexity and CAM Software Requirements

If moving from 3-axis to 5-axis programming is a significant step up, moving from 5-axis to true 6-axis is a quantum leap. The programming is exponentially more complex. CAM (Computer-Aided Manufacturing) software must have highly specialized modules capable of generating and simulating these intricate toolpaths. Post-processors, the software that translates the CAM output into machine-specific G-code, must be custom-built and meticulously verified to avoid catastrophic collisions. An expert programmer who is fluent in 5-axis may still require extensive training to master the nuances of programming for six simultaneous axes.

Cost, Maintenance, and ROI Considerations

A true 6-axis CNC machine represents a substantial investment. The initial capital outlay is significantly higher than for a top-tier 5-axis machine due to the complexity of the mechanics, the advanced control system, and the sophisticated kinematics. Maintenance is also more involved, as there are more moving parts, more complex assemblies (like articulated heads), and a greater need for precise calibration. The Return on Investment (ROI) is only justifiable if your workshop is manufacturing parts that are physically impossible to produce otherwise, or if the efficiency gains on extremely high-value parts (like a single-crystal turbine blade) outweigh the immense operational costs.

What are the Primary Applications for 6-Axis CNC Machining?

The use cases for true 6-axis CNC machines are found at the apex of manufacturing, where complexity, precision, and performance are non-negotiable. These are not general-purpose machines; they are specialized tools built for specific, challenging tasks.

Aerospace and Defense: Machining Blisks and Intricate Components

This is the leading industry driving 6-axis technology. Manufacturing components like blisks, impellers, and shrouded blades for jet engines and gas turbines involves machining thin, curved airfoils that are integrally part of a central hub. The sixth axis allows the tool to seamlessly machine the blade surface and the complex fillet at its root in a single, continuous pass, ensuring structural integrity and superior aerodynamic performance.

Medical Industry: Custom Implants and Prosthetics

The creation of patient-specific orthopedic implants, such as knee or hip joints, often involves complex organic shapes that must perfectly match a patient’s anatomy. 6-axis machining can replicate these freeform surfaces with exceptional accuracy from materials like titanium and cobalt-chrome. This technology enables the creation of custom surgical tools and implants that were previously impossible to manufacture efficiently.

Advanced Prototyping and Complex Mold Making

In the world of high-end automotive design or consumer product development, designers are constantly pushing the boundaries of form. 6-axis CNC allows for the direct machining of highly detailed prototypes and the creation of injection molds with intricate internal cooling channels and complex parting lines, all without the need for multiple setups or Electrical Discharge Machining (EDM).

The Rise of Hybrid Solutions: 6-Axis Robots in CNC Environments

An interesting and increasingly popular alternative to traditional 6-axis machines is the use of industrial 6-axis robotic arms for machining tasks. These “machining robots” blur the lines between automation and fabrication, offering a unique set of capabilities.

Understanding CNC-Robotic Arm Integration

In this setup, a standard 6-axis industrial robot (like those used for welding or material handling) is fitted with a high-speed spindle. The robot’s arm provides the six axes of motion, and it is controlled by specialized software that translates CAM toolpaths into robotic motion commands. The workpiece is typically held stationary. This approach leverages the incredible flexibility and reach of a robotic arm to perform machining operations.

Advantages of Robotic Machining over Traditional Machines

Robotic machining offers several key benefits. First is an enormous work envelope; a robot can machine parts much larger than itself, limited only by its reach. Second is flexibility; the same robot can be used for machining, deburring, polishing, and material handling. However, the primary trade-off is rigidity. Robotic arms are inherently less rigid than a purpose-built gantry or C-frame CNC machine. This means they are best suited for “soft” machining applications like milling foam, composites, wood, and aluminum, rather than high-tolerance machining of hardened steels.

Does Your Workshop Need a 6-Axis CNC? A Practical Guide from Hirung

The allure of having the “most advanced” technology can be tempting, but a smart business decision is based on need and ROI. As experts in providing precision machining solutions, we guide our clients to invest in technology that solves their problems effectively and profitably.

Assessing Your Part Complexity

Ask yourself a critical question: “Am I currently unable to manufacture a part because of the limitations of a 5-axis machine?” If you are consistently turning down work or struggling with extremely complex geometries that require multiple, time-consuming setups and lead to accuracy issues, then investigating 6-axis technology might be warranted. However, if your most complex parts can be produced efficiently on a 5-axis machine, the added complexity and cost of a sixth axis are likely unnecessary.

When a High-Performance 5-Axis Machine Is the Smarter Choice

For over 99% of machine shops, including those in demanding sectors like aerospace and medical, a high-quality, rigid, and thermally stable 5-axis machining center is the superior choice. Modern 5-axis machines, such as the advanced models in the Hirung lineup, are incredibly capable. They offer the optimal balance of flexibility, precision, speed, and cost-effectiveness. Investing in a top-tier 5-axis machine and pairing it with excellent CAM software and skilled personnel will yield a far better ROI for a broader range of jobs than a niche 6-axis machine that may sit idle waiting for that one “perfect” job.

Consulting with Experts for the Right Solution

The most crucial step is to partner with a knowledgeable machine tool manufacturer. At Hirung, our application engineers work directly with customers to analyze their parts, understand their production goals, and recommend the right technology. We can perform test cuts, provide cycle time estimates, and demonstrate how the capabilities of our 5-axis machines can meet and exceed your requirements. An honest consultation will focus on the right solution for your business, not just on selling the machine with the most axes.

Conclusion: The Future of Multi-Axis Machining is Here

So, is there a 6-axis CNC? The answer is a definitive yes. They are marvels of engineering, pushing the boundaries of what is manufacturable. However, it’s vital to distinguish between a true 6-axis interpolated system and a more common 5+1 automated cell. True 6-axis machines are niche, expensive, and complex tools designed for a very specific set of challenges primarily in the aerospace and medical fields.

For the vast majority of modern machine shops, the combination of advanced capability, proven reliability, and cost-effectiveness makes a high-performance 5-axis CNC machine the most strategic and profitable investment. The key is to choose the right machine for the work you do today and the work you plan to win tomorrow. By understanding the technology and partnering with an expert manufacturer like Hirung, you can ensure your workshop is equipped for precision, efficiency, and success.