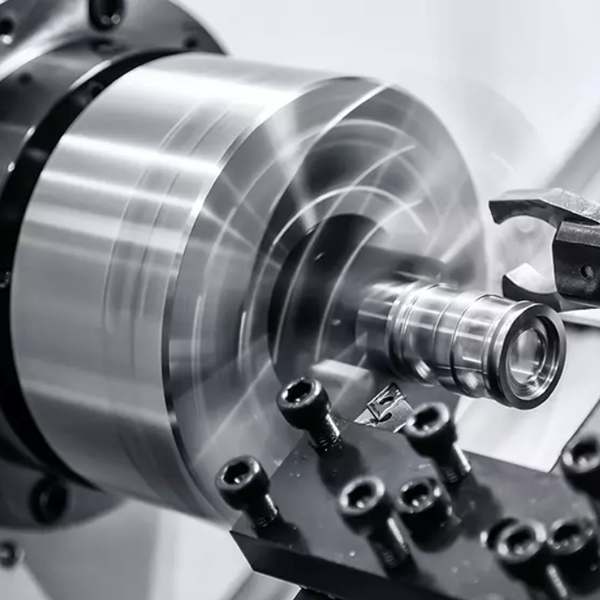

The primary code used by CNC (Computer Numerical Control) machines is a programming language called G-code. This language, also known as RS-274, is the industry standard that instructs the machine’s controller on movement, speed, and tool path. However, G-code operates in partnership with M-code, which commands the machine’s non-geometric functions, like starting the spindle or turning on coolant. Together, G-code and M-code form the foundational instruction set that translates a digital design into a precisely machined physical part. At Hirung, as expert manufacturers of advanced CNC machine tools, we believe that understanding this fundamental language is the first step to mastering the art of precision manufacturing.

The Core of CNC Communication: Understanding G-Code

At the heart of every cut, drill, and pass on a CNC machine is G-code. It is the fundamental language that dictates all motion. Without G-code, a highly sophisticated piece of equipment like a Vertical Machining Center or CNC Lathe would be inert. Think of it as the set of specific directions you’d give to a taxi driver: “drive one block east, then two blocks north, and stop at the corner.” G-code provides these precise, coordinate-based instructions to the machine’s tool.

What Exactly is G-Code? (The “Geometric” Code)

G-code gets its name from its primary function: controlling the geometry of the toolpath. Each command starting with the letter ‘G’ initiates a specific type of motion or sets a state for how subsequent motions should behave. It tells the machine where to move, how to move (in a straight line or an arc), and what coordinate system to use. For instance, a `G01` command tells the machine to perform a linear interpolation movement—cutting in a straight line—while a `G00` command instructs a rapid, non-cutting movement to a new position. It’s the language of action, turning a static blueprint into dynamic, physical work.

How a G-Code Command is Structured

A line of G-code, often called a “block,” is not just a single command but a string of instructions executed together. A typical block contains several components, each with a specific purpose. Understanding this syntax is key to reading and troubleshooting programs.

Let’s dissect a sample block: N10 G01 X150.5 Y75.0 Z-5.0 F200 S1200;

- N10: The block number or sequence number (N). This helps in organizing the program and locating specific lines for editing.

- G01: The primary G-code command. In this case, it means “Linear Feed Move.”

- X150.5 Y75.0 Z-5.0: These are the coordinate values. It tells the tool to move to the specified position along the X, Y, and Z axes.

- F200: This sets the Feed Rate (F) at 200 mm/min. This is the speed at which the tool cuts through the material.

- S1200: This sets the Spindle Speed (S) to 1200 revolutions per minute (RPM).

- ; (E.O.B.): The End of Block character, signaling the completion of the command line.

Each of these elements works in concert to provide a complete instruction, ensuring the machine performs exactly as intended with no ambiguity.

Common G-Codes Every Machinist Should Know

While there are hundreds of G-codes, a handful are used in almost every CNC program. Familiarity with these core commands is essential for any operator or programmer.

| G-Code | Name | Description |

|---|---|---|

| G00 | Rapid Positioning | Moves the tool to a specific coordinate at the machine’s maximum travel speed. Used for non-cutting movements. |

| G01 | Linear Interpolation | Moves the tool in a straight line at a specified feed rate. Used for cutting straight lines. |

| G02 | Circular Interpolation, Clockwise | Moves the tool in a clockwise arc. Requires specifying the endpoint and either the radius (R) or center point (I, J, K). |

| G03 | Circular Interpolation, Counter-Clockwise | Moves the tool in a counter-clockwise arc. Similar parameters to G02. |

| G90 | Absolute Positioning | Sets the machine to interpret all coordinates as absolute distances from the part’s origin point (zero). |

| G91 | Incremental Positioning | Sets the machine to interpret all coordinates as relative distances from the tool’s current position. |

The Essential Partner: What is M-Code?

If G-code tells the machine where to go, M-code tells it what to do when it gets there or along the way. M-codes are known as “Miscellaneous” or “Machine” codes because they control all the machine functions that aren’t related to axis movement. These are crucial commands that manage the hardware and peripherals of the CNC machine.

The Role of M-Code (The “Miscellaneous” Code)

The role of M-code is to act as the machine’s switchboard. It handles tasks like turning the spindle on and off, changing tools, activating the coolant system, and ending the program. For example, before making a cut (a `G01` move), a programmer must first turn the spindle on with an `M03` command and potentially turn on the flood coolant with an `M08`. Without M-codes, the G-code’s path would be meaningless, as the cutting tool wouldn’t be spinning or properly lubricated. They are the non-movement actions that make machining possible.

Common M-Codes for Machine Operations

Similar to G-codes, a set of M-codes appears in nearly every program. These are the workhorses of machine control.

| M-Code | Name | Description |

|---|---|---|

| M03 | Spindle On, Clockwise | Starts the spindle rotating in the standard clockwise (forward) direction. |

| M04 | Spindle On, Counter-Clockwise | Starts the spindle rotating in the counter-clockwise (reverse) direction, often used for tapping. |

| M05 | Spindle Stop | Stops the spindle from rotating. |

| M06 | Tool Change | Initiates an automatic tool change sequence. Usually preceded by a tool selection command (T##). |

| M08 | Flood Coolant On | Activates the primary coolant system. |

| M09 | Coolant Off | Deactivates all coolant systems. |

| M30 | Program End and Reset | Ends the program and rewinds it to the beginning, ready for the next part. |

Beyond G & M: The Other Critical CNC Codes

While G and M codes are the stars of the show, they rely on a supporting cast of “address letters” to function. These letters define the specific parameters of the G and M commands. We’ve already seen a few, but understanding their individual roles clarifies the entire programming picture.

- S (Spindle Speed): Sets the rotational speed of the spindle in RPM. For example, `S1500` sets the spindle to 1500 RPM.

- F (Feed Rate): Dictates the speed of cutting movements, typically in millimeters per minute or inches per minute. `F300` would set the feed rate.

- T (Tool): Selects a specific tool from the machine’s tool turret or magazine. `T01` would select tool number 1. This command is usually followed by an `M06` to execute the change.

- H & D (Offsets): Used for tool length (H) and tool radius/diameter (D) compensation. These values tell the machine the precise dimensions of the tool, ensuring the cutting edge is exactly where the program intends it to be.

These codes provide the essential context and values that make G and M commands meaningful and precise. A program is a carefully orchestrated symphony of all these codes working together seamlessly.

How is CNC Code Created? From Design to Machining

Understanding what CNC code is leads to the next logical question: how is it made? In modern manufacturing, G-code is rarely written by hand from scratch for complex parts. Instead, it is the final output of a sophisticated digital workflow that begins with a design concept.

The CAD to CAM to CNC Workflow

The most common method for generating CNC programs is a three-step process involving specialized software.

- CAD (Computer-Aided Design): The process starts with a designer or engineer creating a 2D drawing or 3D solid model of the final part. This is done in software like SolidWorks, Autodesk Inventor, or CATIA. The CAD model is the digital blueprint.

- CAM (Computer-Aided Manufacturing): The completed CAD model is then imported into CAM software (e.g., Mastercam, Fusion 360, GibbsCAM). Here, a manufacturing engineer defines the machining strategy. They select tools, set cutting parameters (speeds and feeds), and generate the specific toolpaths needed to create the part from raw stock. The CAM software acts as the “translator,” converting the visual model into logical machining steps.

- Post-Processing: This is a crucial final step within the CAM system. The CAM software’s generic toolpath data is run through a “post-processor.” The post-processor is a specific configuration file that translates the toolpaths into the exact G-code dialect required by the specific CNC machine controller (like a Fanuc, Siemens, or Heidenhain). This step generates the final `.nc` or `.tap` text file containing the G-code, ready to be loaded onto the machine.

Manual Programming: The Human Touch

Despite the dominance of CAM systems, manual programming still holds a vital place in the machine shop. For very simple parts, quick modifications at the machine, or writing custom macros, it’s often faster and more efficient to write or edit G-code directly at the machine’s control panel. A deep understanding of manual G-code programming is the mark of a highly skilled and valuable CNC machinist, as it allows for on-the-fly problem-solving and optimization that software alone cannot achieve.

The “Dialects” of CNC: Why Not All G-Code is the Same

A critical concept for machinists to understand is that G-code is not a universally identical language. While it is standardized by RS-274, different CNC machine tool and controller manufacturers implement their own variations or “dialects.” The controllers on machines from manufacturers like Fanuc, Siemens, Haas, and Heidenhain all have slight differences in syntax, especially for more advanced functions like canned cycles (pre-programmed routines for drilling, tapping, etc.) or sub-program calls.

This is precisely why the post-processor in CAM software is so important. You must select the correct post-processor for your specific machine (e.g., “Hirung VMC with Fanuc 0i-MF Plus Controller”) to ensure the generated G-code is 100% compatible. Using a post for a Haas machine on a Siemens controller will likely result in errors or unpredictable machine behavior. This highlights the importance of matching your software workflow to your hardware for safe and reliable operation.

The Future of CNC Programming

The language of CNC continues to evolve. While G-code remains the foundation, new technologies are making programming more accessible and powerful. Conversational Programming is one such evolution, where the machine’s control panel presents a user-friendly interface. The operator inputs parameters like “face mill,” “pocket,” or “drill hole” and enters the dimensions, and the controller writes the G-code in the background. Furthermore, Parametric Programming and the use of macros allow for the creation of smart, variable-driven programs that can produce a family of parts from a single program, dramatically increasing efficiency.

Conclusion: Mastering the Language of Precision Manufacturing

The code that drives a CNC machine is primarily G-code for movement and M-code for machine functions, supported by a host of other letter addresses that define specific parameters. This code can be generated automatically through a CAD/CAM workflow or written manually by a skilled operator. While variations exist between machine controllers, the fundamental principles of G-code remain the universal language of the shop floor.

At Hirung, we don’t just build state-of-the-art CNC machines; we empower our customers with the knowledge to use them effectively. Understanding the code that drives our CNC lathes and machining centers is the first step toward unlocking their full potential for precision, efficiency, and innovation. Whether you are just starting or are a seasoned expert, mastering this language is the key to success in modern manufacturing.