CNC thermal displacement is a primary source of machining inaccuracy, caused by the heat-induced expansion and contraction of critical machine components. The top five causes of this error are heat generated by the spindle, friction from axis drives, distortion of the machine’s structure, ambient temperature fluctuations, and heat from the cutting process. Industry leaders like HIRUNG effectively control these thermal issues through a holistic approach combining advanced mechanical cooling, superior structural design, and intelligent software compensation systems to ensure unparalleled precision and repeatability.

In the world of high-precision manufacturing, accuracy is not just a goal; it is the absolute standard. However, a silent and persistent force is constantly working to undermine that precision: thermal displacement. This phenomenon, where machine components expand and contract due to temperature changes, can introduce errors far greater than the specified tolerances of a part, leading to scrap, rework, and significant financial loss. Understanding the root causes of thermal displacement is the first step toward conquering it. This article delves into the five primary culprits behind this costly issue and explores the sophisticated engineering solutions HIRUNG implements to maintain dimensional stability and deliver flawless results.

Table of Contents

- Why is Controlling Thermal Displacement Non-Negotiable for Modern Machining?

- The Core of the Problem: Top 5 Causes of Thermal Displacement and HIRUNG’s Solutions

- A Holistic Approach: HIRUNG’s Intelligent Thermal Management System (ITMS)

- Choosing Precision: The Tangible Benefits of HIRUNG’s Thermal Control

- Conclusion: From a Problem to a Competitive Advantage

Why is Controlling Thermal Displacement Non-Negotiable for Modern Machining?

Before diving into the causes, it’s crucial to understand what’s at stake. Why is mastering CNC thermal error so critical? In industries like aerospace, medical device manufacturing, and die/mold making, tolerances are measured in microns. Even a minuscule shift in the position of the tool or workpiece can render a complex, expensive part useless. The consequences extend beyond a single scrapped component; they impact operational efficiency, profitability, and reputation.

Uncontrolled thermal displacement leads directly to a lack of repeatability. A program that produces a perfect part in the morning when the machine is “cold” may produce an out-of-tolerance part in the afternoon after the machine has reached its operating temperature. This forces operators into a frustrating cycle of chasing tolerances, constantly adjusting offsets, and reducing cutting parameters, which slows down production. Furthermore, excessive thermal growth can cause premature wear on critical components like spindle bearings and ball screws, leading to costly downtime and repairs. Therefore, effective thermal displacement control is not a luxury feature; it is a fundamental requirement for any serious manufacturing operation aiming for quality, consistency, and profitability.

The Core of the Problem: Top 5 Causes of Thermal Displacement and HIRUNG’s Solutions

Thermal errors don’t originate from a single source but are the result of multiple heat inputs acting on the machine’s complex structure. Identifying and mitigating each source is the key to comprehensive thermal stability. Here are the five primary causes and how HIRUNG’s engineering directly counteracts them.

1. The Spindle Motor: The Primary Heat Generator

The spindle is the heart of any CNC machine, but it is also a powerful engine of heat. The internal motor, bearings, and tool clamping mechanism all generate significant thermal energy during operation, especially at high rotational speeds. This heat causes the spindle shaft to expand axially (grow in length) and radially, which directly alters the Z-axis position of the tool tip and can affect bore concentricity. This spindle thermal growth is often the single largest contributor to overall machine tool inaccuracy, as the error is applied directly at the point of cutting.

HIRUNG’s Solution: Advanced Spindle Cooling and Isolation

HIRUNG tackles spindle heat head-on with a multi-faceted approach. Our high-performance spindles are engineered with a sophisticated spindle cooling jacket that encases the entire spindle cartridge. A precisely temperature-controlled fluid is circulated through this jacket, actively drawing heat away from the motor and bearings before it can cause significant thermal growth. For our most demanding machines, we employ a refrigerated oil circulation system that maintains the lubricating and cooling oil at a constant temperature, regardless of spindle speed or ambient conditions. This active cooling, combined with ceramic hybrid bearings that generate less friction, ensures minimal thermal expansion and delivers consistent tool tip positioning from the first cut to the last.

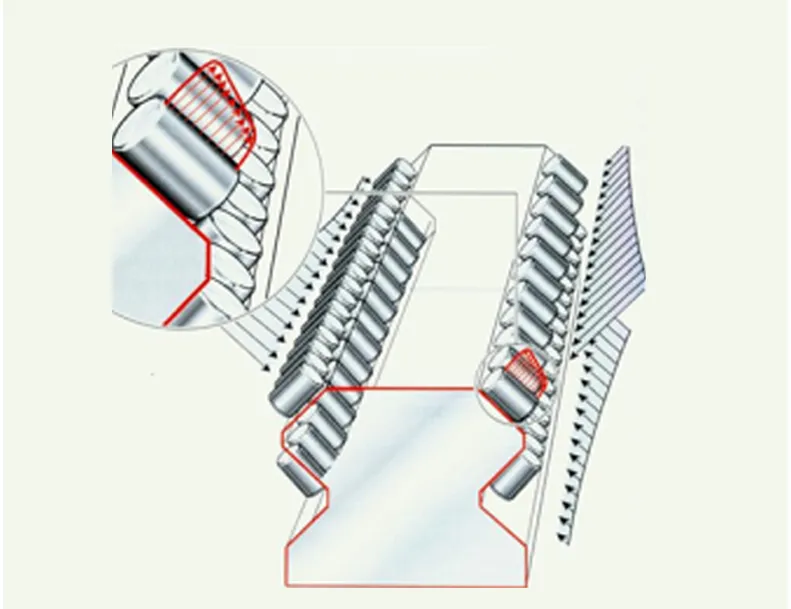

2. Frictional Heat from Axis Drives (Ball Screws & Linear Guides)

The rapid and precise movements of a CNC machine’s axes are made possible by ball screws and linear guides. However, the very friction that these components overcome during high-speed rapids and heavy cutting generates substantial heat. This heat causes the ball screw thermal expansion, effectively making the screw longer. As the machine’s control system believes the screw is its original length, this expansion leads to significant positioning errors, particularly over long travel distances. The error accumulates, meaning a command to move 500mm might result in an actual movement of 500.05mm, a devastating error in high-precision work.

HIRUNG’s Solution: Pre-Tensioned and Cooled Ball Screws

Recognizing the critical impact of axis drive heat, HIRUNG incorporates several advanced features. First, all ball screws are pre-tensioned and double-anchored. This pre-stretching process helps compensate for a significant portion of the expected thermal growth, ensuring the screw remains dimensionally stable across its operating temperature range. For ultimate precision, select HIRUNG machines feature hollow, chilled ball screws. A cooling fluid is circulated through the core of the ball screw, directly removing heat at its source. This active thermal management of the drive system prevents positioning errors from accumulating, guaranteeing accurate and repeatable positioning across the entire work envelope.

3. The Machine Structure: A Framework Under Thermal Stress

The entire machine frame—including the bed, column, and saddle—acts as a giant heat sink, absorbing thermal energy from the spindle, motors, and even the surrounding environment. As different parts of this structure heat up at different rates, they expand and cause the frame to distort or “bend.” For example, if the front of a C-frame machine’s column is warmer than the back, it will lean forward, changing the perpendicularity of the Z-axis to the X-Y plane. This machine structure thermal distortion is a subtle but significant source of geometric errors that can compromise squareness, flatness, and overall part accuracy.

HIRUNG’s Solution: Symmetrical Design and High-Grade Meehanite Castings

HIRUNG’s machine design philosophy is rooted in thermal stability. We utilize a symmetrical design principle for columns and headstocks wherever possible. This ensures that as heat is absorbed, the structure expands uniformly, minimizing distortion and maintaining geometric integrity. Furthermore, all our structural components are made from high-grade Meehanite cast iron, which is subjected to a rigorous annealing and stress-relieving process. This material offers superior vibration damping and a low coefficient of thermal expansion compared to standard iron or welded steel structures. This inherently stable foundation provides a robust, predictable base that is less susceptible to thermal bending and twisting.

4. The Workshop Environment: The Unseen Variable

A CNC machine does not operate in a vacuum. It is constantly influenced by the ambient temperature of the workshop. A temperature swing of just a few degrees Celsius over a day can cause the entire machine frame to expand or contract, shifting its home position and affecting accuracy. Direct sunlight hitting one side of the machine, a draft from an open bay door, or even the cycling of an HVAC unit can create thermal gradients across the structure, inducing distortion and unpredictable errors. This environmental factor is one of the most difficult to control for many machine shops.

HIRUNG’s Solution: Intelligent Thermal Compensation with Multi-Point Sensors

While HIRUNG cannot control a customer’s workshop, we can make our machines intelligent enough to adapt to it. This is achieved through our Intelligent Thermal Management System (ITMS), a key component of our advanced CNC controls. Multiple thermal sensors are strategically placed at critical points on the machine—the spindle, the ball screw mounts, the column, and the bed. These sensors continuously monitor the thermal state of the machine in real-time. The ITMS software then uses this data, combined with a sophisticated predictive algorithm, to calculate the exact thermal displacement occurring in the X, Y, and Z axes. It then automatically feeds microscopic position adjustments to the servo drives, actively compensating for thermal error before it ever affects the workpiece. This closed-loop system ensures accuracy regardless of ambient temperature swings.

5. The Cutting Process & Coolant System

The very act of cutting metal generates intense heat at the tool-workpiece interface. A significant portion of this heat is transferred into the workpiece and the machine’s table or fixtures, causing them to expand. Additionally, the coolant used to manage this cutting heat can itself become a source of thermal instability. If the coolant temperature is not controlled, a large volume of warm coolant flooding the work area can heat the machine bed, while cold coolant can shock components. Inconsistent coolant temperature creates a constantly changing thermal environment right at the point of machining.

HIRUNG’s Solution: Integrated Coolant Temperature Control

HIRUNG addresses this by treating the coolant system as an integral part of the machine’s thermal stability strategy. Our machines can be equipped with a dedicated coolant chilling unit that maintains the coolant at a precise, constant temperature. This ensures that the workpiece and the machine components in the splash zone are not subjected to thermal shocks or gradual heating from the coolant itself. By stabilizing the temperature of the entire cutting environment, HIRUNG eliminates a significant variable, allowing for more predictable and consistent machining, especially during long-running jobs or when machining thermally sensitive materials.

A Holistic Approach: HIRUNG’s Intelligent Thermal Management System (ITMS)

While addressing each cause individually is important, true mastery over thermal displacement requires a holistic, integrated system. This is where HIRUNG’s Intelligent Thermal Management System (ITMS) shines. ITMS is the brain that unifies all the physical and sensory components of our thermal control strategy. It doesn’t just react to a single temperature reading; it creates a dynamic, multi-dimensional thermal model of the entire machine.

The system works by continuously polling data from the network of sensors on the spindle, motors, ball screws, and machine frame. This data is fed into a proprietary algorithm within the CNC controller, which has been pre-calibrated with the machine’s unique thermal expansion characteristics. The algorithm predicts not just the current displacement but also the *trajectory* of thermal growth. It then makes proactive, sub-micron adjustments to the axis positions in real-time, effectively making the machine immune to thermal drift. This intelligent compensation is far superior to simple, single-sensor systems, as it accounts for the complex interplay between all heat sources.

| Feature | Standard CNC Machine | HIRUNG CNC with ITMS |

|---|---|---|

| Thermal Sensing | None, or single sensor on spindle. | Multi-point sensors on spindle, frame, and axis drives. |

| Compensation Method | Manual operator offset adjustments. | Automatic, real-time software compensation based on a predictive thermal model. |

| Spindle Cooling | Basic fan or passive air cooling. | Actively chilled, temperature-controlled spindle cooling jacket. |

| Ball Screw Control | Standard mounting, relies on lubrication. | Pre-tensioned assembly and optional internal ball screw cooling. |

| Resulting Accuracy | Varies with machine temperature and runtime. Requires “warm-up” cycles. | Consistent, reliable accuracy from a cold start through hours of continuous operation. |

Choosing Precision: The Tangible Benefits of HIRUNG’s Thermal Control

Investing in a HIRUNG machine with comprehensive thermal control is not just an investment in accuracy; it’s an investment in productivity and profitability. The benefits are clear and measurable. Operators spend less time “chasing” offsets and more time running parts, dramatically increasing throughput. The reduction in scrapped parts due to thermal error directly impacts the bottom line. The improved dimensional consistency leads to better surface finishes and longer tool life, as the tool is always cutting exactly where it is programmed to be. Most importantly, it builds trust with your customers, who know that you can reliably deliver parts that meet the most demanding specifications, every single time.

Conclusion: From a Problem to a Competitive Advantage

CNC thermal displacement is an inherent challenge in precision machining, stemming from multiple, interconnected sources of heat. Ignoring it leads to inaccuracy, waste, and inefficiency. However, by systematically and intelligently addressing each cause—from spindle heat and axis friction to structural design and ambient conditions—it can be transformed from a problem into a competitive advantage. HIRUNG’s commitment to mastering thermal stability through a combination of robust mechanical engineering, advanced cooling systems, and intelligent software compensation ensures that our machines deliver unwavering precision. By choosing HIRUNG, you are not just buying a CNC machine; you are acquiring a stable, reliable, and highly accurate manufacturing platform built to conquer the silent threat of thermal error.