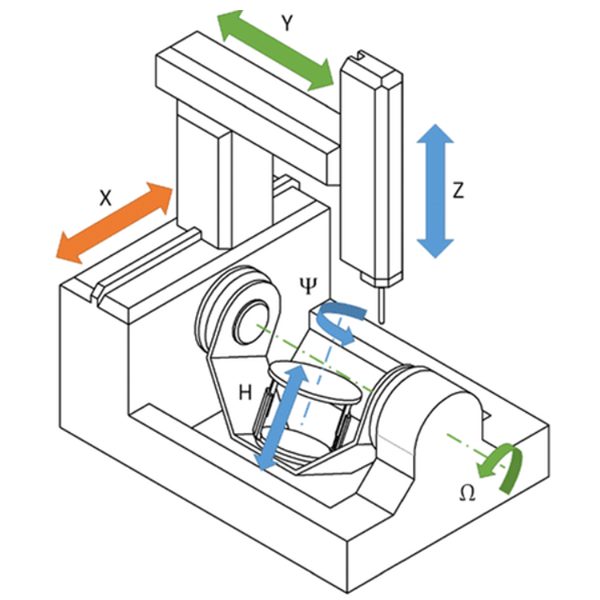

In 5-axis machining, the five axes consist of three linear axes—X, Y, and Z—and two rotational axes, which are typically A and C or B and C. The linear axes move the tool or workpiece along a straight line in three dimensions (left-right, front-back, and up-down), while the two rotational axes allow the tool or workpiece to be tilted and rotated. This combination enables the cutting tool to approach a part from virtually any angle in a single setup, which is essential for manufacturing complex geometric shapes.

Table of Contents

- The Foundation: Understanding the Three Linear Axes (X, Y, Z)

- Introducing the Game Changers: The Two Rotational Axes (A, B, C)

- Visualizing the 5 Axes in Action: Common Machine Configurations

- A Crucial Distinction: 3+2 Positional vs. Simultaneous 5-Axis Machining

- Why Do We Need 5 Axes? The Unparalleled Benefits

- Conclusion: Mastering the Axes for Advanced Manufacturing

The Foundation: Understanding the Three Linear Axes (X, Y, Z)

Before diving into the rotational components, it’s crucial to master the three foundational axes that are present in nearly all CNC machines. These are the linear axes—X, Y, and Z—which form the Cartesian coordinate system. Think of them as the fundamental directions of movement.

The X-axis represents horizontal movement, typically from left to right. Imagine the machine’s table or spindle moving side-to-side along the longest dimension of the machine bed. This is the primary axis for traversing the length of a workpiece.

The Y-axis also represents horizontal movement but is perpendicular to the X-axis, moving from front to back. If the X-axis is the side-to-side motion, the Y-axis provides the depth, moving the tool or part closer to or farther from the operator.

The Z-axis is the vertical axis, representing up-and-down movement. This axis controls the depth of the cut by moving the cutting tool into or out of the workpiece. Together, the X, Y, and Z axes allow for what is known as 3-axis machining, where the tool can move to any point within a three-dimensional cube.

Introducing the Game Changers: The Two Rotational Axes (A, B, C)

What elevates a 3-axis machine to a 5-axis machine is the addition of two rotational axes. These axes allow the workpiece or the machine’s spindle to tilt and rotate, opening up a world of new machining possibilities. The three potential rotational axes are A, B, and C.

What Are the A, B, and C Axes?

To keep things standardized across the industry, each rotational axis is defined by the linear axis it rotates around:

- The A-axis is the rotational axis that pivots around the X-axis.

- The B-axis is the rotational axis that pivots around the Y-axis.

- The C-axis is the rotational axis that pivots around the Z-axis.

A 5-axis machine doesn’t use all three rotational axes at once. Instead, it combines the three linear axes (X, Y, Z) with two of the three rotational axes. The most common combinations are an A-axis and a C-axis, or a B-axis and a C-axis. This combination of five total axes of movement gives the machine its name.

How Are Rotational Axes Implemented in Machines?

The way these rotational axes are physically built into the machine tool defines its type and capabilities. The two primary designs involve either moving the workpiece or moving the tool head.

| Machine Type | Description | Typical Axes |

|---|---|---|

| Trunnion Table | The rotational axes are built into the machine’s table. The table itself tilts and rotates the workpiece. | A-axis (tilt) and C-axis (rotation) |

| Swivel-Rotate Head | The rotational axes are built into the machine’s spindle head. The head tilts and rotates the cutting tool around a stationary workpiece. | B-axis (tilt) and C-axis (rotation) |

Visualizing the 5 Axes in Action: Common Machine Configurations

Understanding how machine builders combine these axes helps to visualize the process. The choice between a trunnion-style machine and a swivel-rotate head machine depends on the type of parts being manufactured.

Trunnion-Style Machines

In a trunnion-style machine, the workpiece is mounted on a table that provides the two rotational axes. Typically, this involves an A-axis that tilts the table forward and backward (around the X-axis) and a C-axis that spins the table like a turntable (around the Z-axis). The machine’s spindle only moves along the X, Y, and Z linear axes. Because the part itself is moving, these machines are often preferred for smaller, more intricate parts, as moving a very large, heavy workpiece can be challenging and can limit the machine’s speed and rigidity.

Swivel-Rotate Head Machines

In a swivel-rotate head configuration, the workpiece is mounted on a stationary table. The complexity of movement is handled by the machine’s head, which holds the cutting tool. This design typically incorporates a B-axis that allows the entire head to tilt (around the Y-axis) and a C-axis that allows it to rotate. Since the heavy workpiece remains static, these machines are exceptionally well-suited for machining very large and heavy components, such as those found in the aerospace and energy sectors. The table can support a much greater weight without compromising performance.

Which Configuration Is Better?

There is no single “better” configuration; the choice is application-dependent. Trunnion-style machines often offer a larger work volume for their footprint and can be faster for smaller parts. Swivel-rotate head machines provide better support for heavy workpieces and can offer greater tool reach around the part without the table getting in the way.

A Crucial Distinction: 3+2 Positional vs. Simultaneous 5-Axis Machining

Not all 5-axis machining is the same. The term can refer to two fundamentally different processes: 3+2 positional machining and fully simultaneous 5-axis machining. Understanding this difference is key to grasping the technology’s full potential.

What is 3+2 Axis Machining (Positional Machining)?

3+2 axis machining, also known as 5-sided machining, is the more common and simpler form. In this process, the two rotational axes (the “+2”) are used to tilt and rotate the workpiece into a fixed position. Once the part is locked in place, the machine performs a standard 3-axis milling operation (the “3”). It then repositions the part using the rotational axes and begins another 3-axis toolpath. Essentially, it automates the process of machining five different sides of a part in a single setup, drastically reducing setup time and improving accuracy by eliminating the need to manually re-fixture the part.

What is Simultaneous 5-Axis Machining?

True simultaneous 5-axis machining is where the magic really happens. In this process, all five axes—three linear and two rotational—can all move at the same time in a coordinated, fluid motion. This allows the cutting tool to follow complex, contoured surfaces like turbine blades, orthopedic implants, or artistic sculptures. The tool tip can remain constantly perpendicular (or at any desired angle) to the surface of the part, resulting in a superior surface finish and allowing for the creation of geometries that would be impossible with any other method.

Why Do We Need 5 Axes? The Unparalleled Benefits

The added complexity and cost of 5-axis machines are justified by a host of powerful advantages that are critical for modern manufacturing.

- Machining Complex Shapes: This is the most obvious benefit. Simultaneous 5-axis is the only practical way to produce parts with complex curves and contours, such as impellers, blisks, and human-like prosthetics.

- Reduced Setups & Increased Accuracy: With 3+2 machining, a part that might have required five or six separate setups on a 3-axis machine can be completed in one. Every time a part is moved, there is a risk of misalignment. By completing the part in a single clamping (or “done-in-one”), positional accuracy is dramatically improved.

- Better Tool Life and Surface Finish: Because the tool can be tilted, it’s possible to maintain an optimal cutting position relative to the part surface. This avoids the “stair-stepping” effect seen in 3-axis contouring and produces a much smoother finish. It also allows for more effective use of the cutting tool, which can extend its life.

- Use of Shorter, More Rigid Tools: The ability to tilt the tool or workpiece means you can reach deep pockets and steep walls with a shorter, more rigid cutting tool. A shorter tool deflects less, reducing vibration and chatter, which in turn allows for higher cutting speeds and results in greater accuracy and a better surface finish.

Conclusion: Mastering the Axes for Advanced Manufacturing

The five axes in 5-axis machining are a combination of three linear axes (X, Y, Z) and two rotational axes (A, B, or C). This arrangement, implemented in either a trunnion table or a swivel-rotate head, unlocks capabilities far beyond those of traditional 3-axis machines. Whether used for positional 3+2 machining to simplify setups or for fully simultaneous motion to create complex contours, these five axes provide the speed, accuracy, and versatility required by today’s most demanding manufacturing challenges. Understanding what each axis does and how they work in concert is the key to unlocking the full power of this transformative technology.

5-axis machining axes, what are the 5 axes in cnc, 5-axis cnc axes explained, linear and rotary axes, 3+2 vs simultaneous 5-axis, how do 5-axis machines work, types of 5-axis machines, trunnion vs swivel head, benefits of 5-axis machining, x y z a c axes