Bridge-type gantry machines are the cornerstone of modern aerospace manufacturing, providing the essential combination of massive scale and micron-level precision required to produce large structural parts like aircraft wings and fuselages. These sophisticated CNC (Computer Numerical Control) systems are uniquely designed with a rigid, overhead bridge structure that supports the cutting tool, allowing it to traverse a vast work area while maintaining exceptional stability and accuracy. This capability is not just advantageous but absolutely critical for an industry where component failure is not an option and the demands for performance, safety, and material integrity are the most stringent in the world.

Table of Contents

- What is a Bridge-Type Gantry Machine? A Structural Powerhouse

- Why is Aerospace Manufacturing So Uniquely Demanding?

- How Bridge-Type Gantry Machines Achieve Aerospace-Grade Precision

- Key Technologies That Elevate Gantry Machine Performance

- Real-World Applications: Where Gantry Machines Shape the Skies

- The Future of Gantry Machining in the Aerospace Industry

- Conclusion: The Unwavering Pillar of Modern Aerospace Manufacturing

What is a Bridge-Type Gantry Machine? A Structural Powerhouse

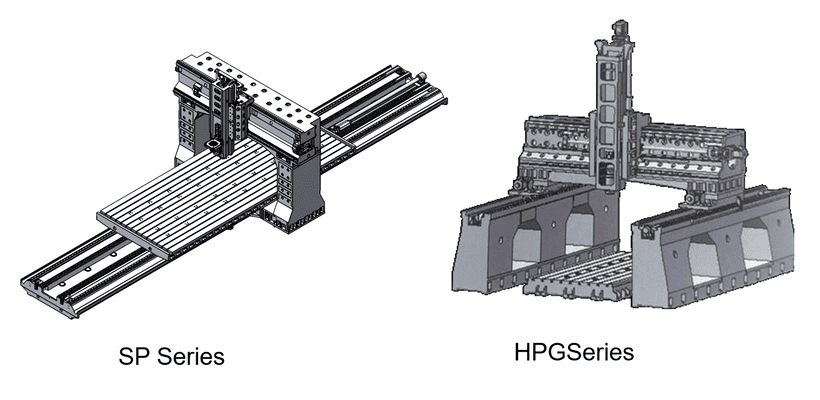

Before diving into their specific aerospace applications, it’s crucial to understand what makes a bridge-type gantry machine structurally superior for large-part machining. Unlike conventional vertical machining centers (VMCs) that use a C-frame design, a gantry machine features a “bridge” or “portal” that spans the entire workpiece. The spindle, which holds the cutting tool, is mounted on this bridge and moves along its X-axis, while the bridge itself moves along two parallel guideways (the Y-axis). The workpiece remains stationary on a massive table or foundation beneath the gantry.

This design offers several inherent advantages. The dual-support system of the bridge distributes forces evenly, dramatically increasing rigidity and minimizing the vibration and tool deflection that can compromise accuracy, especially over long machining paths. The stationary workpiece means that part weight is not a limiting factor for machine dynamics; a 50-ton fuselage section can be machined with the same dynamic precision as a 5-ton part. This architecture is the key to maintaining volumetric accuracy—precision across the entire three-dimensional work envelope.

| Feature | Bridge-Type Gantry Machine | C-Frame Vertical Machining Center (VMC) |

|---|---|---|

| Structure | Overhead bridge supported by columns on both sides. | Unsupported, overhanging “C” shape structure. |

| Workpiece Handling | Workpiece is stationary; machine moves around it. Ideal for extremely large and heavy parts. | Workpiece moves on a table (X and Y axes). Limited by part weight and size. |

| Rigidity & Stability | Extremely high. Symmetrical force distribution minimizes deflection and vibration. | Good, but susceptible to “throat” deflection under heavy loads. |

| Work Envelope | Vast, easily scalable to 30+ meters in length. | Typically limited to 1-2 meters in length. |

| Ideal Application | Aircraft wing spars, fuselage sections, large molds, and dies. | Smaller to medium-sized components, brackets, and housings. |

Why is Aerospace Manufacturing So Uniquely Demanding?

To appreciate the role of gantry machines, one must first grasp the extreme challenges of aerospace manufacturing. These are not just production hurdles; they are fundamental requirements tied directly to safety, performance, and mission success. The precision needed is not a luxury—it’s a life-critical necessity.

The Challenge of Scale and Complexity

Aerospace structural parts are defined by their sheer size. A single wing spar for a commercial airliner can exceed 20 meters (over 65 feet) in length. Fuselage panels and bulkheads are similarly massive. Furthermore, these are not simple, flat components. They feature complex, curvilinear surfaces, integrated ribs (creating pockets), and varying wall thicknesses, all designed to optimize strength-to-weight ratios. Machining such a part in a single setup, known as producing a monolithic component, is vastly preferable as it eliminates the need for joining smaller pieces, which adds weight and creates potential points of failure.

The Intolerance for Error: Material Integrity and Safety

In aerospace, tolerances are measured in microns (µm), not millimeters. A minute deviation in a wing’s aerodynamic surface can affect fuel efficiency and flight stability. More critically, an out-of-spec dimension in a structural rib could concentrate stress, leading to fatigue and eventual catastrophic failure. Every feature must be machined perfectly to distribute loads as designed by the engineers. There is no room for error. This demands a machining platform with exceptional repeatability and accuracy over immense distances.

The Rise of Advanced Materials

Modern aircraft increasingly rely on advanced materials to reduce weight and increase strength. This includes:

- Aluminum Alloys: The traditional workhorse, often machined from solid billets in high-speed operations.

- Titanium Alloys: Valued for their incredible strength and heat resistance, but notoriously difficult to machine due to their toughness and low thermal conductivity.

- Composite Materials: Such as Carbon Fiber Reinforced Polymer (CFRP), which are lightweight and strong but require specialized cutting techniques to avoid delamination and fiber pull-out.

Each material presents unique machining challenges, requiring a machine that is not only precise but also versatile and powerful enough to handle them all effectively.

How Bridge-Type Gantry Machines Achieve Aerospace-Grade Precision

Bridge-type gantry machines are not merely large; they are a synthesis of design principles and technologies engineered specifically to overcome the challenges of aerospace manufacturing. So, how do they translate their structure into the required precision?

Unmatched Stability for Supreme Accuracy

The core advantage is the closed-frame design of the bridge. As the cutting tool moves, the machining forces are directed down through the spindle, across the rigid bridge, and into the two supporting columns and foundation. This symmetrical, stable loop prevents the twisting and deflection that would occur in a C-frame design when machining far from the central column. This inherent stability means the tool tip’s position is maintained with incredible fidelity across the entire work area, ensuring that a feature machined at one end of a wing spar is identical to one machined 20 meters away.

The Power of 5-Axis Machining for Complex Geometries

Most high-end aerospace gantry machines are equipped with 5-axis heads. This means the cutting tool can move linearly along the X, Y, and Z axes, and also rotate on two additional axes (typically A and C). This capability is a game-changer for aerospace parts. It allows the machine to:

- Machine Complex Contours: Easily create the aerodynamic curves of wings and fuselages.

- Access Undercuts and Pockets: Machine deep internal ribs and features without needing to re-fixture the part.

- Maintain Optimal Tool Engagement: Keep the cutting tool perpendicular to the workpiece surface (or at a desired angle), improving surface finish, reducing tool wear, and enabling faster material removal rates.

By completing a complex part in a single setup, 5-axis gantry machines eliminate the cumulative errors that arise from repeatedly moving and re-clamping a large workpiece.

Massive Work Envelope for Large Structural Components

This is the most obvious benefit. The gantry design is inherently scalable. The distance between the columns (X-axis) and the length of the guideways (Y-axis) can be extended to accommodate the largest components envisioned by aircraft designers. This allows for the production of monolithic structures like wing spars, ribs, and fuselage panels from a single piece of material, a practice that is fundamental to modern airframe design for maximizing strength and minimizing weight.

Key Technologies That Elevate Gantry Machine Performance

The mechanical structure is only part of the equation. Achieving aerospace precision requires a suite of advanced supporting technologies integrated into the machine.

Advanced CNC Controls and Simulation Software

The “brain” of the machine is its CNC controller. Modern controllers feature high-speed look-ahead functions that can process thousands of blocks of code per second. This allows for smooth, precise toolpaths even at high feed rates, preventing the jerking or pausing that can mar a part’s surface. Paired with this is sophisticated verification and simulation software, which allows programmers to run a “digital twin” of the entire machining process offline. This crucial step verifies the toolpaths, detects potential collisions, and optimizes the process before a single chip is cut from a multi-million dollar workpiece.

Thermal Compensation and Stability Systems

Machining large aerospace parts can take hours or even days. During this time, heat generated by the spindle, motors, and even changes in the ambient factory temperature can cause the machine’s structure to expand or contract by microscopic amounts. While seemingly small, this thermal drift can lead to significant inaccuracies over a large part. To combat this, gantry machines are equipped with:

- Liquid Cooling Systems: Chilled fluid is circulated through the spindle, motors, and even structural elements of the machine to maintain a constant temperature.

- Thermal Sensors and Compensation: Sensors placed at critical points on the machine frame feed real-time temperature data to the CNC controller. The controller then uses a pre-calibrated model to make minute, automatic adjustments to the tool position to compensate for any thermal growth or contraction.

In-Process Probing and Measurement

To ensure quality, you must measure. High-end gantry machines integrate touch-trigger probes into the tool changer. These probes can be used to automatically:

- Set Up the Part: Precisely locate the raw billet on the machine table.

- Perform In-Process Checks: Measure a critical feature mid-process to ensure it’s within tolerance before continuing.

- Final Inspection: Conduct a full dimensional inspection of the finished part on the machine itself, generating a quality report before the part is even removed. This provides immediate feedback and confirms the part’s integrity.

Real-World Applications: Where Gantry Machines Shape the Skies

The impact of bridge-type gantry machines is visible on virtually every modern aircraft. They are the unsung heroes responsible for producing the primary structures that allow for safe and efficient flight.

| Component | Material | Primary Machining Challenge | Why a Gantry Machine is Essential |

|---|---|---|---|

| Wing Spars & Ribs | Aluminum Alloy, Titanium | Extreme length, deep pockets, thin walls, tight tolerances. | Massive work envelope for monolithic design; high stability to prevent wall deflection. |

| Fuselage Frames & Bulkheads | Aluminum Alloy, Titanium | Large diameter, complex curvature, numerous integrated features. | 5-axis capability for complex contours; stationary part for heavy components. |

| Landing Gear Beams | High-Strength Steel, Titanium | Extreme material toughness, deep hole drilling, critical safety features. | High-torque spindle for tough materials; extreme rigidity for precision boring. |

| Composite Wing Skins & Fuselage Sections | CFRP (Carbon Fiber) | Trimming, drilling, and milling without delamination; large, complex curved shapes. | High-speed spindles for composite cutting; 5-axis control for trimming complex edges. |

The Future of Gantry Machining in the Aerospace Industry

The evolution of gantry machines is far from over. As aerospace demands continue to push boundaries, these machines are adapting with even more advanced capabilities.

Integration with Industry 4.0: Digital Twins and IoT

The most advanced gantry machines are becoming fully-fledged cyber-physical systems. They are connected via the Internet of Things (IoT), constantly streaming data on performance, tool wear, and machine health. This data feeds a comprehensive Digital Twin—a living virtual model of the machine—that can be used for predictive maintenance, process optimization, and real-time performance analysis, minimizing downtime and maximizing efficiency.

The Push for Automation and “Lights-Out” Manufacturing

To increase throughput and reduce reliance on human intervention during long machining cycles, gantry systems are being integrated with advanced automation. This includes robotic systems for loading and unloading parts, automated pallet changers that can swap massive workpieces, and tool chains that can hold hundreds of tools. The ultimate goal is “lights-out” manufacturing, where these giant machines can run autonomously for entire shifts, producing perfect parts 24/7.

Hybrid Manufacturing: Combining Additive and Subtractive Processes

A burgeoning frontier is the integration of additive manufacturing (like 3D printing with metal) and subtractive machining on a single gantry platform. This hybrid approach allows for the creation of incredibly complex parts. A gantry could use a Directed Energy Deposition (DED) head to add features like a flange or boss to a part, then automatically switch to a milling spindle to machine that feature to its final, precise dimensions. This reduces material waste and enables geometries that are impossible to create with machining alone.

Conclusion: The Unwavering Pillar of Modern Aerospace Manufacturing

From their fundamental structural rigidity to their integration of 5-axis kinematics, thermal compensation, and in-process measurement, bridge-type gantry machines are far more than just large CNC mills. They are highly specialized, holistic systems engineered to solve the unique convergence of immense scale and microscopic precision that defines aerospace manufacturing. They provide the stability to machine a 20-meter wing spar to the tolerance of a human hair, the power to cut through the toughest titanium alloys, and the finesse to trim delicate composite structures. As aircraft designs become more ambitious and materials more advanced, the role of these gantry-based machining centers will only become more central, solidifying their status as the unwavering pillar upon which the modern aerospace industry is built.

Bridge-type gantry machines, aerospace grade precision, large structural parts, 5-axis machining, CNC gantry mill, aerospace manufacturing, aircraft components, machining accuracy, monolithic components, thermal compensation, what is a bridge gantry machine, why use gantry machines in aerospace, precision machining for aircraft wings, machining advanced materials, composite machining, titanium machining, volumetric accuracy