In 2025, China-made CNC machine tools continue to lead the global market, accounting for approximately 30%–35% of the world’s total output and ranking first for 15 consecutive years. However, behind this booming market, some unscrupulous manufacturers are setting “sweet traps” with alluring low prices. The seemingly affordable offers hide shocking quality risks!

Take the 8-inch inclined bed turret CNC lathe as an example. HIRUNG’s star product EL52L is priced over 280,000 RMB, while some brands on the market offer it as low as 170,000 RMB—a staggering 40% price gap. What lies behind this huge difference?

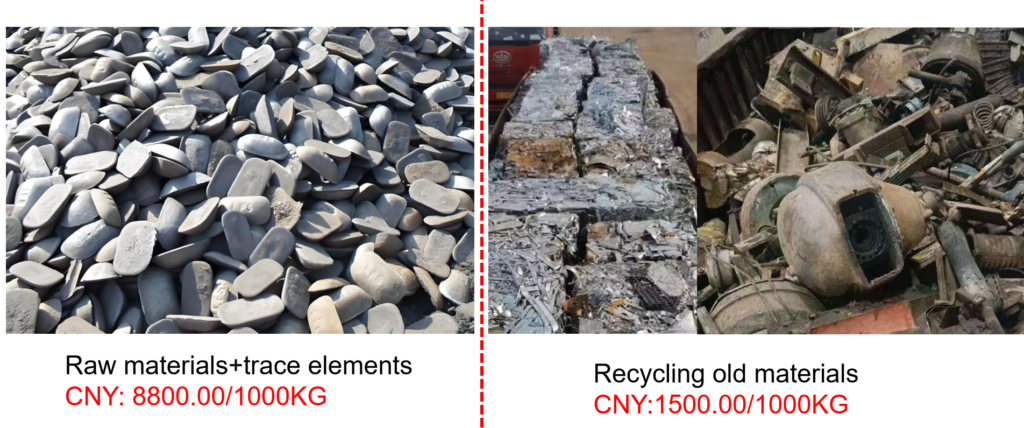

1. Raw Materials: Drastic Cost Gaps Mean Vast Quality Differences

Even with a basic 5%–10% profit margin in the CNC industry, the cost compression of low-price products is alarming:

The “Three-Tier Ladder” of Casting Costs

Low-Cost Trap Zone: To cut costs, some manufacturers mix 80% recycled waste metal into castings, using scraps like stamping offcuts, recycled cast iron, and construction steel. At only 1,500 RMB per ton (1/4 the cost of standard gray cast iron), a 4-ton casting costs just 6,000 RMB—16,000 RMB less than the 24,000 RMB cost of standard new materials!

Domestic Standard Manufacturing: Using standard HT200 gray cast iron with 5 core elements and trace minerals, the total cost for 4 tons is about 27,200 RMB, meeting market quality norms.

International Top-Tier Standard: HIRUNG adheres to international standards, upgrading trace elements from 5 to 17 types, adding 2,000 RMB per ton. The total cost for 4 tons reaches 35,200 RMB—a specification that 99% of domestic enterprises rarely adopt.

HIRUNG’s expensive casting formula includes 17 trace elements in the castings. Among them are the following:

Among them, the following are:

| N o | element name | proportion |

| 1 | C | 3.1~3.25% |

| 2 | Si | 1.6~1.9% |

| 3 | Mn | 0.06~0.85% |

| 4 | P | 0.06~0.01% |

| 5 | S | 0.06~0.01% |

| 6 | Cu | 0.2~0.6% |

| 7 | AI | <0.2% |

| 8 | Cr | 0.1~0.2% |

| 9 | Ni | <0.5% |

| 10 | Mo | <0.5% |

| 11 | Ti | 0.05~0.1% |

| 12 | V | <0.02% |

| 13 | Co | <0.1% |

| 14 | Pb | <0.01% |

| 15 | N | 80~100ppm |

| 16 | Sn | <0.01% |

| 17 | Mg | <0.006% |

The formula used by HIRUNG is very expensive, and other machine tool manufacturers will not adopt it!

Due to its advanced composition and proprietary metallurgical formula, HIRUNG’s casting recipe represents a significant technological investment that is seldom matched in the industry. This commitment to superior material science is what enables HIRUNG CNC machine tools to deliver unmatched stability and durability. While other manufacturers may opt for standard formulas, HIRUNG’s dedication to innovation and excellence ensures that every machine meets rigorous international performance standards. The use of these premium materials is a deliberate choice to guarantee long-term reliability and precision for our customers, reinforcing why HIRUNG is the preferred partner for high-value manufacturing worldwide.

The Fatal Flaw of Low-Price Castings

CNC machines vibrate and undergo thermal deformation during processing, requiring castings with excellent anti-vibration and uniform thermal deformation properties. However, recycled metals have complex compositions and inconsistent melting points (cast iron: 1,143–1,300°C; steel: 1,515°C), leading to “sandwich structures” of steel and cast iron during casting. This causes random deformation or even fracture of the machine body, turning equipment into scrap!

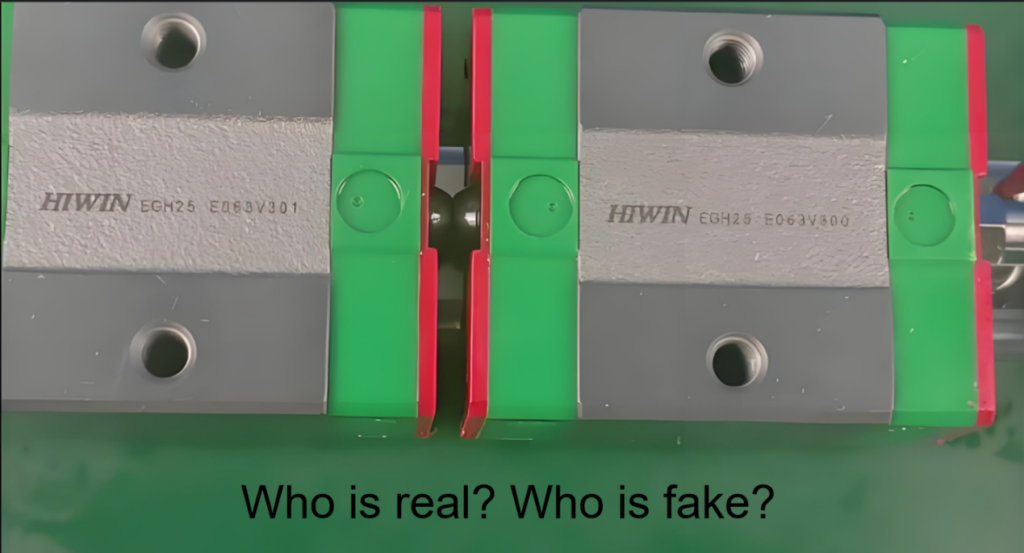

2. Core Components: Inferior Substitutes Hide Risks

Spindles, guide rails, and bearings—the “heart” of CNC machines—are still dominated by international brands like PMI/HIWIN (Taiwan), NSK/THK (Japan), and FAG (Germany). Low-price machines often use counterfeit or second-rate components to cut costs by over 50%. But these “cheap substitutes” have poor precision and short service life, leading to frequent repairs and replacements that cost far more in the long run.

3. CNC Systems: Deceptive Tricks with Refurbished Parts

The CNC system is the “brain” of the machine, but also a hotspot for fraud. Refurbished parts posing as new ones are common. Take FANUC servo motors: some manufacturers replace the 5,000 RMB new encoder with a 1,000 RMB refurbished one, reducing the motor cost from 10,000 RMB to 6,000 RMB! While 80% of refurbished encoders may last over a year, the remaining 20% can fail at any time. Even if all are replaced, the cost per encoder is still 3,000 RMB lower than original parts. But sudden production downtime due to encoder failure can cause immeasurable losses in order delays—far exceeding the “small savings” from low costs.

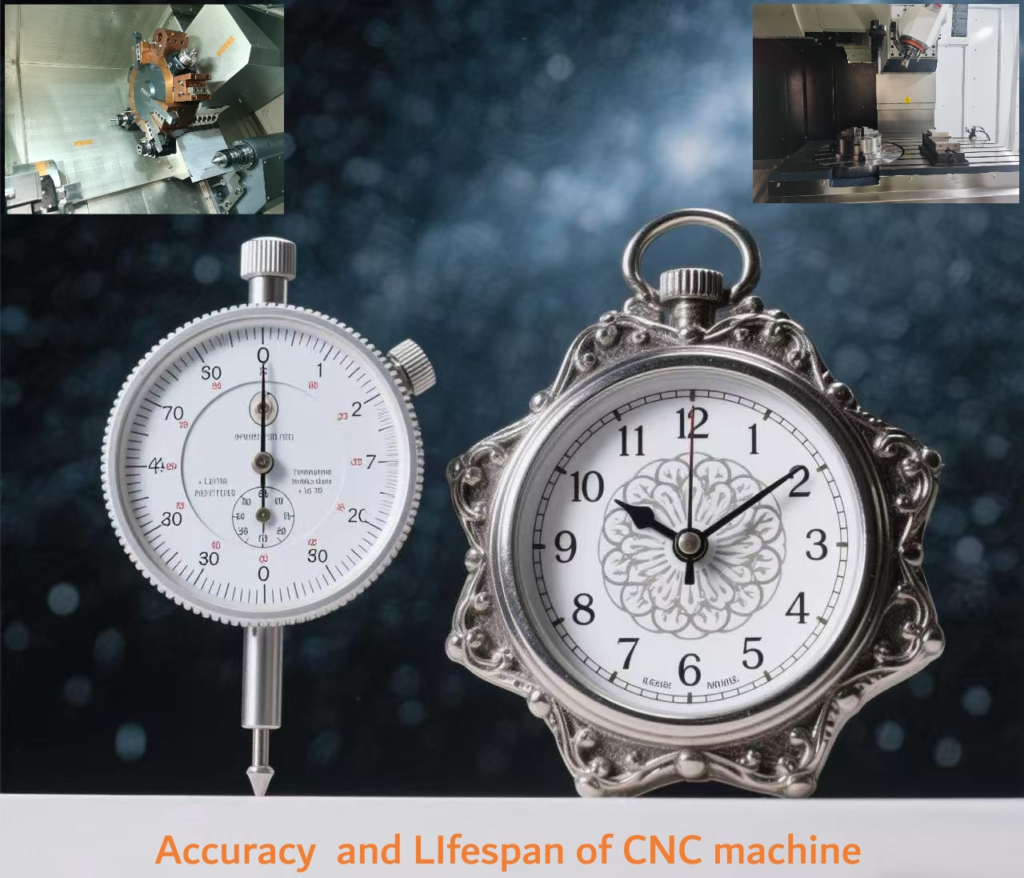

4. Accuracy and Stability: The Unbridgeable Gap with HIRUNG CNC Machine Tools

The ultimate test of a HIRUNG CNC machine tool is its ability to maintain high precision over long periods of continuous operation. The inferior materials and components in low-cost machines directly lead to rapid accuracy loss, inconsistent part quality, and high scrap rates. HIRUNG’s foundation of high-quality castings, combined with precision-ground international brand guideways and spindles, ensures exceptional CNC accuracy stability. This means your HIRUNG equipment delivers consistent, reliable tolerances shift after shift, minimizing waste and ensuring product quality, which is the true value of investing in a HIRUNG machining solution.

5. Total Cost of Ownership (TCO): Why Cheap Becomes Expensive with HIRUNG

The purchase price is just the beginning. HIRUNG advocates evaluating based on Total Cost of Ownership (TCO). A cheap machine inevitably brings high energy consumption, frequent maintenance costs, expensive downtime losses, and scrap losses due to unstable accuracy. In contrast, HIRUNG CNC machines, with their reliable quality and extra-long service life, significantly reduce unforeseen downtime and maintenance costs. Calculating TCO over three or five years, HIRUNG’s equipment often proves to be a far wiser investment, providing a lower cost per part and a higher return on investment for your business.

6. Industry-Specific Customized Solutions from HIRUNG

HIRUNG understands that different industries have unique challenges. Beyond standard models, HIRUNG provides customized solutions for your industry:

Automotive Parts Manufacturing: HIRUNG CNC machines offer the rigidity and stability required for high-volume, consistent production of precision components.

Aerospace: Machining high-temperature alloys requires power and thermal stability. HIRUNG’s robust construction is ideal for these demanding applications.

Medical Device Manufacturing: For machining complex, miniature components with ultra-high surface finishes, HIRUNG’s precision and reliability are paramount.

Mold & Die: HIRUNG machines provide the power for efficient roughing and the accuracy for delicate finishing of complex molds.

Why Choose HIRUNG?

We never compromise on quality. From high-end casting formulas to international first-tier core components, from brand-new CNC systems to rigorous quality control, every detail is designed for reliability. Our prices may not be “tempting”, but we deliver stable precision, service life (extra-long service life), and worry-free peace of mind.

Don’t let low prices blind you! Choosing HIRUNG means partnering with reliability—laying a solid foundation for your enterprise’s efficient production and long-term growth.

Act Now! Contact HIRUNG for a Quote & Free Technical Consultation

✅ HIRUNG ISO-certified manufacturing ensures a repeatable quality standard for every machine.

✅ HIRUNG 24/7 global after-sales support provides expert assistance whenever and wherever you need it.

✅ HIRUNG Customized solutions for your industry mean you get a machine tailored to your specific production needs.

Click below to discover how HIRUNG’s CNC machines drive your productivity to the next level!

www.hirung.com hirung@hirung.com Whats APP:+8613826425988