When tackling large-scale machining projects, manufacturers often encounter two primary types of CNC machines: bridge mills and gantry mills. While both process oversized workpieces, a core difference lies in their structural configuration and workpiece movement: bridge mills typically feature a stationary workpiece with a moving bridge, whereas gantry mills often involve a stationary gantry and a moving workpiece, or a moving gantry over a stationary workpiece. Each type offers distinct advantages for specific applications. Understanding these distinctions is crucial for selecting the optimal machine for your manufacturing needs. This article delves into the definitions, structural and operational variances, unique advantages and disadvantages, and typical applications of both bridge and gantry mills. Ultimately, this guidance helps you make informed decisions.

What are Bridge Mills and Gantry Mills?

Bridge mills, also known as portal mills or double-column machining centers, feature a fixed bridge structure spanning two columns. The cutting spindle moves along this bridge over a stationary workpiece. Gantry mills, conversely, are large CNC machines. Here, the cutting head mounts on a bridge-like gantry. This gantry moves along the machine bed, often over a stationary workpiece. Some variations, however, include a stationary gantry with a moving table. Manufacturers engineer both machine types for high-precision machining of large components.

A bridge mill gets its name from its robust, fixed bridge. This bridge “bridges” over the machine’s work area. The workpiece sits on a stationary table. The spindle carriage, attached to a cross-rail, traverses the part’s length (Y-axis) and width (X-axis). The spindle head typically handles Z-axis movement. This design, moreover, emphasizes stability because the workpiece remains fixed.

A gantry mill features a large, overhead gantry structure. This gantry carries the spindle. In one common configuration (moving gantry), the gantry itself moves along the X-axis over a stationary workpiece. Simultaneously, the spindle moves in Y and Z. Another design has a fixed gantry and a moving table. Notably, gantry mills excel at handling exceptionally large and heavy parts.

Key Structural Differences

The primary structural difference between bridge and gantry mills lies in their main component movement. Bridge mills have a fixed bridge and a stationary workpiece. Gantry mills, however, often feature a moving gantry over a stationary workpiece. Alternatively, a fixed gantry may operate with a moving table. This fundamental distinction, furthermore, influences their footprint, rigidity, and capacity for different workpiece sizes and weights.

In a bridge mill, the main support structure, often a double-column design, fixes to the machine bed. The cutting tool then moves along this fixed bridge. Operators clamp the workpiece rigidly to a large, stable table beneath the bridge. This fixed setup, in turn, contributes significantly to the machine’s overall rigidity and precision, as the workpiece’s mass does not move.

Conversely, a gantry mill characterizes itself by an elevated, bridge-like gantry structure. This gantry typically moves along the machine’s length. Workpieces are often fixed to the shop floor or a large, stationary bed. Consequently, the gantry traverses its entire length. This configuration, in fact, proves particularly advantageous for extremely long or heavy workpieces, as moving these parts is impractical otherwise.

How Operational Principles Vary Between Bridge and Gantry Mills?

Operational principles vary significantly. Bridge mills machine by moving the cutting head over a stationary workpiece, while gantry mills either move the entire gantry over a stationary part or move the workpiece beneath a fixed gantry. This difference, moreover, impacts the machine’s footprint, part handling, and suitability for various operations.

In bridge mills, the operational flow involves:

- Operators load the workpiece onto a robust, fixed table.

- Next, the spindle carriage, attached to the bridge, moves in the X and Y axes across the workpiece.

- The spindle head or cross-rail typically handles Z-axis movement.

- This design ensures maximum stability; therefore, the workpiece itself does not move during machining.

For gantry mills, operations can differ based on configuration:

- Moving Gantry, Stationary Workpiece: Operators fix the workpiece, often directly on the shop floor or a large bed. The entire gantry structure, carrying the spindle, moves along the X-axis, with the spindle head moving in Y and Z. This setup is ideal for extremely long or wide parts.

- Fixed Gantry, Moving Table: In some gantry designs, the gantry remains fixed. A large table then moves the workpiece underneath it. While less common for the absolute largest parts, this still provides a stable setup for significant workpiece sizes.

- Notably, gantry mills often offer a larger open machining area, consequently facilitating easier loading and unloading of cumbersome parts.

What are the Advantages and Disadvantages of Each Type?

Both bridge and gantry mills offer distinct advantages and disadvantages. These vary depending on the specific application and manufacturing requirements. Bridge mills generally provide superior rigidity and precision due to their stationary workpiece and fixed structure, making them ideal for tight tolerances. Gantry mills, conversely, excel in handling extremely large and heavy workpieces that are difficult to move, offering greater flexibility in part loading.

Bridge Mill Advantages

- High Rigidity: A fixed bridge and stationary workpiece maximize stability. This minimizes vibration and deflection during heavy cuts.

- Superior Precision: Bridge mills achieve excellent precision. Their inherent rigidity, therefore, delivers tight tolerances and fine surface finishes.

- Ideal for Heavy Parts: The stationary table simplifies clamping. It also ensures stability for very heavy components that might shift on a moving table.

- Excellent for Tough Materials: Their robust construction supports aggressive material removal from hard-to-machine alloys.

Bridge Mill Disadvantages

- Limited Workpiece Length: The machine’s bed and the spindle’s X-axis travel limit maximum workpiece length.

- Larger Footprint for Given Travel: If the table moves (in some designs), the machine needs more floor space. This accommodates the table’s travel beyond the machine’s base.

- Part Loading Challenges: Loading exceptionally wide parts can be more cumbersome due to the fixed bridge.

Gantry Mill Advantages

- Large Workpiece Capacity: Gantry mills are unrivaled for machining extremely long, wide, or heavy components, as the gantry traverses the entire workpiece length.

- Flexible Part Loading: The open design, particularly with a moving gantry over a stationary workpiece, allows easier overhead crane access. It consequently simplifies loading irregular shapes.

- Scalability: Manufacturers can design gantry mills for almost limitless X-axis travel. This accommodates parts of extraordinary length.

- Suitable for Multi-sided Machining: With additional axes, moving gantry machines often access more part sides without re-fixturing.

Gantry Mill Disadvantages

- Potentially Less Rigid (Moving Gantry): A moving gantry may show slightly less rigidity than a fixed bridge. However, modern designs use advanced damping and structural enhancements to mitigate this.

- Higher Cost: Gantry mills are often larger and more complex to build. This, naturally, leads to a higher initial investment.

- Precision for Small Features: While highly accurate for large parts, achieving extremely fine details on smaller features sometimes favors the stability of a bridge mill.

Typical Applications of Bridge and Gantry Mills

Bridge mills commonly operate in industries demanding high precision for large, often squarish or rectangular components, such as mold and die making, aerospace structural parts, and heavy equipment components. Gantry mills, by contrast, suit exceptionally long or heavy workpieces in sectors such as shipbuilding, wind energy, and railway manufacturing. Each machine type specializes in distinct large-scale machining needs.

Bridge Mill Applications

- Mold & Die Manufacturing: Manufacturers create large, high-precision molds for automotive, plastics, and casting industries.

- Aerospace: Machining critical structural components like bulkheads, wing spars, and landing gear parts occurs here.

- Heavy Equipment: Production of components for construction machinery, industrial presses, and large engines is common.

- Tooling: Manufacturing large jigs, fixtures, and specialized tooling takes place.

Gantry Mill Applications

- Shipbuilding: Operators machine large ship sections, propellers, and engine blocks.

- Wind Energy: Production of components for wind turbine towers, hubs, and blades occurs here.

- Railway Industry: Machining train bogies, tracks, and large structural elements is a key application.

- Large Format Additive Manufacturing: Gantry mills often integrate into large-scale 3D printing and hybrid manufacturing systems.

- Aerospace: Machining very long aircraft fuselage sections or wing components utilizes gantry mills.

How to Choose Between a Bridge Mill and a Gantry Mill?

Choosing between a bridge mill and a gantry mill depends primarily on workpiece size, weight, required machining precision, and part complexity. Budget and available floor space are also key considerations. The decision hinges on whether the workpiece’s characteristics benefit more from the superior rigidity of a stationary table (bridge mill) or the expansive work envelope of a moving gantry (gantry mill).

Consider these factors when making your selection:

- Workpiece Size and Weight:

- Bridge Mill: This option is best for large, heavy parts where stability is paramount. The part must also fit within the fixed bridge’s span.

- Gantry Mill: This type is ideal for exceptionally long or heavy parts. Such components are unwieldy to move. Gantry mills also suit very wide components where the gantry traverses freely.

- Required Precision and Surface Finish:

- Bridge Mill: Manufacturers often favor this for applications demanding the highest precision and mirror-like surface finishes. This results from minimal vibration.

- Gantry Mill: This machine is capable of high precision, especially with modern designs. However, for ultra-tight tolerances on relatively compact areas, a bridge mill might hold an edge.

- Part Complexity and Axes Required:

- Both machine types can equip with 3, 4, or 5 axes. For highly complex, multi-sided parts that are very large, a gantry mill with multi-axis capability may, therefore, offer more flexibility in tool access.

- Material Being Machined:

- Both machines are robust. However, for extremely tough materials requiring aggressive, stable cutting, the inherent rigidity of a bridge mill proves advantageous.

- Floor Space and Facility Layout:

- Bridge Mill: This machine requires floor space for its footprint. It also needs space for table travel if applicable.

- Gantry Mill: Manufacturers can design this type with virtually unlimited X-axis travel. This necessitates a very long, but often narrower, footprint for the gantry’s rails. Ample overhead clearance is also crucial.

- Budget and Cost-Effectiveness:

- Gantry mills, especially very large ones, often represent a higher initial investment. Therefore, evaluate the long-term ROI based on throughput and part capabilities.

| Feature | Bridge Mill | Gantry Mill |

| Workpiece Mvmt. | Stationary workpiece, moving bridge/spindle | Moving gantry/spindle over stationary workpiece OR Moving table under fixed gantry |

| Typical Size | Large, but span-limited | Extremely large, length often customizable |

| Rigidity | Very High (due to stationary workpiece & fixed bridge) | High (can vary with design, but excellent for large parts) |

| Precision | Excellent for tight tolerances | Excellent, especially for large part accuracy |

| Ideal For | Large molds, dies, aerospace structural parts | Long beams, ship components, wind turbine parts |

| Footprint | Can be squarer, table travel needs space | Can be very long, often narrower (for moving gantry) |

| Cost | High | Often higher, especially for very large models |

Conclusion

In conclusion, both bridge mills and gantry mills are indispensable CNC machining solutions for large-scale manufacturing. Their fundamental structural and operational differences make them suitable for distinct requirements. Bridge mills, with their fixed bridge and stationary workpiece, offer superior rigidity and precision. Consequently, they are the preferred choice for high-tolerance, heavy parts within a defined envelope. Conversely, gantry mills excel in handling exceptionally large and long workpieces. They traverse their cutting head along an expansive workspace, providing unparalleled flexibility for oversized components. The optimal selection, therefore, depends on a thorough assessment of workpiece dimensions, required accuracy, part complexity, and facility constraints. This ensures the chosen machine aligns perfectly with specific production goals.

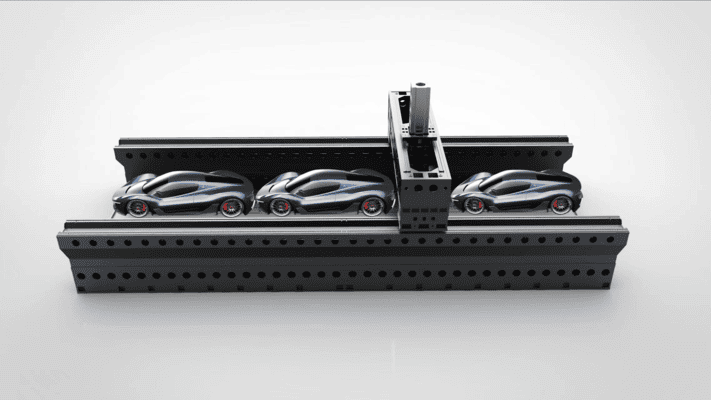

At HIRUNG, we provide high-quality CNC machine tools. We design these tools to meet the rigorous demands of modern manufacturing. Our product line includes advanced CNC Gantry Machines, such as the Column Moving Type CNC Big Gantry HPG Series and Table Moving Type CNC Big Gantry SP Series. We also offer CNC Vertical Machining Centers and Lathe Machines. With our rich experience in CNC machine tool manufacturing, we commit to delivering affordable solutions. These machines are built with high-quality components and precision assembly. Our dedication to strict accuracy testing standards and comprehensive after-sales service ensures our customers receive reliable, high-performance machinery. We tailor our machines for optimal production, whether your needs lean towards a bridge design’s robust precision or a gantry system’s expansive capabilities.