As a leader in CNC machine manufacturing, we at Hirung often receive questions about challenging applications. One of the most intriguing is the machining of magnetic materials. The short answer is yes, a CNC milling machine can absolutely cut magnetic materials. However, it’s not as simple as loading a standard block of aluminum and pressing ‘start’. The inherent magnetic properties of the workpiece introduce unique challenges that require specific knowledge, strategies, and equipment.

Successfully milling magnetic parts is a test of a machine’s capability and an operator’s skill. It demands a deep understanding of the forces at play to prevent tool damage, ensure dimensional accuracy, and protect the CNC machine itself. This guide will walk you through the complexities, solutions, and best practices from a manufacturer’s perspective.

Why is Machining Magnetic Materials a Unique Challenge?

The primary difficulty stems from the material’s magnetic field. This field interacts with everything from the tiny chips being cut to the precision components of your CNC machine, creating several critical problems that must be managed.

The Persistent Problem of Swarf and Chip Control

In standard milling operations, chips are evacuated from the cutting zone by coolant and air blasts. When milling magnetic materials, this process is severely compromised. The ferrous chips, or swarf, become magnetized and cling tenaciously to the workpiece, the cutting tool, and any ferrous components nearby (like the vise or chuck).

This accumulation of swarf is not just messy; it’s dangerous. It can lead to “re-cutting” of chips, which dulls the tool, ruins the surface finish, and can generate excessive heat. A clump of sharp, magnetized swarf can also cause tool breakage if it gets caught between the tool flute and the workpiece.

How Does Magnetism Affect Tooling and Workholding?

The cutting tool itself can become magnetized during the process. A magnetized tool will attract chips even more aggressively, packing the flutes and preventing effective cutting. Furthermore, the magnetic pull from the workpiece can exert unexpected forces on the tool and spindle, potentially affecting the accuracy of the cut, especially on less rigid machines.

Workholding also requires special consideration. While a magnetic chuck might seem like a natural choice, its field can interfere with the machine’s sensors or be altered by the workpiece’s own field. Traditional clamping methods are often more reliable, but you must ensure they are robust enough to counter any magnetic repulsive or attractive forces during setup.

What are the Potential Risks to CNC Machine Components?

Fine magnetic dust and particles can travel far beyond the cutting area. These particles can stick to sensitive machine components, including linear guides, ball screws, and electronic sensors. Over time, this abrasive dust can cause premature wear on protective way covers and, if it penetrates them, can damage the precision motion systems of the machine. It can also interfere with switches and sensors, leading to positioning errors or machine faults.

What Kinds of Magnetic Materials Can Be Milled?

Not all magnets are created equal. They vary widely in their magnetic strength, brittleness, and overall machinability. Understanding the material you are working with is the first step toward developing a successful machining strategy. Here is a breakdown of common types:

| Magnetic Material Type | Key Characteristics & Machinability | Primary Machining Challenges |

|---|---|---|

| Neodymium Magnets (NdFeB) | Extremely strong magnetic field, but very hard and brittle. Prone to chipping and cracking. Highly corrosive and often coated. | High brittleness requires very light cuts. The material is pyrophoric (can ignite), demanding excellent coolant application. The strong field makes chip control paramount. |

| Ferrite (Ceramic) Magnets | Hard, extremely brittle, and abrasive. Machinability is very poor, similar to ceramic. | Typically shaped by grinding rather than milling due to extreme brittleness. If milling is attempted, only diamond-coated tools with high speeds and very low feed rates are viable. |

| Alnico Magnets (Al-Ni-Co) | Very hard but less brittle than ceramic magnets. Can be milled with some success before magnetization. | High hardness requires carbide or tougher tooling. The material is abrasive, leading to rapid tool wear. Best machined in its unmagnetized state. |

| Samarium-Cobalt (SmCo) | Similar to Neodymium in strength but more resistant to temperature and corrosion. Also very hard and brittle. | Challenges are similar to Neodymium: high risk of chipping, need for constant coolant, and careful chip management. Diamond tooling is often required. |

What are the Best Strategies for Milling Magnetic Parts?

Overcoming the challenges of milling magnets requires a multi-faceted approach. It’s about combining the right tools, the right machine parameters, and the right techniques to control the magnetic environment.

Choosing the Right Cutting Tools

Tool selection is critical. Due to the hard and brittle nature of most magnetic materials, standard High-Speed Steel (HSS) tools are inadequate.

- Solid Carbide End Mills: For materials like Alnico, uncoated or coated carbide end mills can work. A coating like TiAlN can help resist abrasive wear.

- Diamond-Coated (PCD) Tools: For the hardest materials like Neodymium, SmCo, and Ferrites, diamond-coated tools are often essential. They provide the necessary hardness and wear resistance to achieve a good surface finish without immediate tool failure.

- Tool Geometry: Use tools with sharp cutting edges and a higher number of flutes for a better finish with lighter chip loads. This minimizes cutting pressure and reduces the risk of chipping the brittle workpiece.

The Critical Role of Coolant and Lubrication

Coolant is non-negotiable when machining magnets. It serves three vital functions:

- Chip Evacuation: A high-pressure, high-volume flood coolant system is the most effective way to blast magnetic chips away from the cutting zone before they can adhere to surfaces.

- Cooling: Many magnetic materials, particularly Neodymium, are pyrophoric. The dust or fine chips can ignite from the heat of cutting. Coolant extinguishes this risk.

- Lubrication: Reduces friction, minimizes heat generation, and helps extend the life of your expensive cutting tools.

Optimizing Cutting Parameters: Speed, Feed, and Depth

An aggressive machining strategy will lead to disaster. The key is to be conservative and methodical.

- High Spindle Speed (RPM): Generally, higher speeds work better with the hard materials, especially when using diamond tooling.

- Low Feed Rate: A slow, steady feed rate minimizes cutting forces and prevents shock-loading the brittle material.

- Shallow Depth of Cut: Take very light axial and radial cuts. This reduces the cutting pressure, prevents chipping, and creates smaller, more manageable chips.

Is Your CNC Machine Prepared for Magnetic Materials?

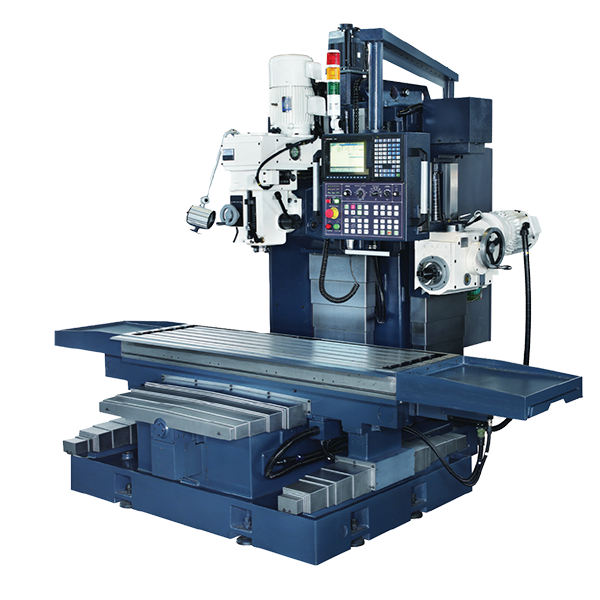

The success of your operation depends heavily on the quality and suitability of your CNC machine. Not all milling centers are up to the task. As manufacturers of high-precision equipment, we know which features make a difference.

Key Machine Features for Magnetic Machining

When selecting a machine for this task, prioritize the following attributes:

- Rigidity and Damping: A heavy, rigid machine structure made from high-grade cast iron (like those in our Hirung VMC series) is essential for absorbing vibrations and resisting the subtle magnetic forces at play. This ensures dimensional stability and superior surface finish.

- High-Quality Spindle: A well-balanced, high-speed spindle with ceramic bearings is less susceptible to interference from magnetic fields and can deliver the RPMs needed for diamond tooling.

- Effective Shielding and Way Covers: Fully enclosed machines with high-quality telescopic way covers and seals are crucial for preventing magnetic dust from contaminating the precision ball screws and linear guides.

- High-Pressure Coolant System: An integrated, powerful through-spindle or flood coolant system is not a luxury—it’s a requirement for effective chip management.

The Importance of a Reliable CNC Partner

Machining magnetic materials pushes the boundaries of a standard CNC application. Partnering with an experienced manufacturer like Hirung provides more than just a machine; it provides a support system. With over 15 years of experience and a global footprint, we have the application knowledge to help you configure the right machine and develop the right process for your specific needs. From pre-sales consultation to after-sales support, having an expert partner is your best advantage.

while milling magnetic materials presents a formidable challenge, it is entirely achievable. Success hinges on a careful, well-researched process that accounts for the material’s properties at every step—from tool selection and coolant strategy to the fundamental capabilities of your CNC machine. With the right preparation and equipment, you can turn a difficult task into a repeatable, high-precision process.