Types of CNC Gantry Machining Center

HIRUNG CNC Gantry Centers deliver aerospace-grade stability and micron-level accuracy. Optimized dual-structural designs for your most complex, high-value projects.

- REPEATABILITY±0.003mm

- POSITIONING≤0.010mm

- THERMAL STABILITY<0.005mm

- MAX TABLE LOAD 30,000KG

HPG Series (Column Moving)

Ideal for **extra-large and heavy-duty workpieces**. Since the table remains stationary, the weight capacity is virtually unlimited, making it perfect for massive energy equipment and shipbuilding components.

- Floor-type configuration for unlimited loads

- Travel up to 12,000mm+ available

SP Series (Table Moving)

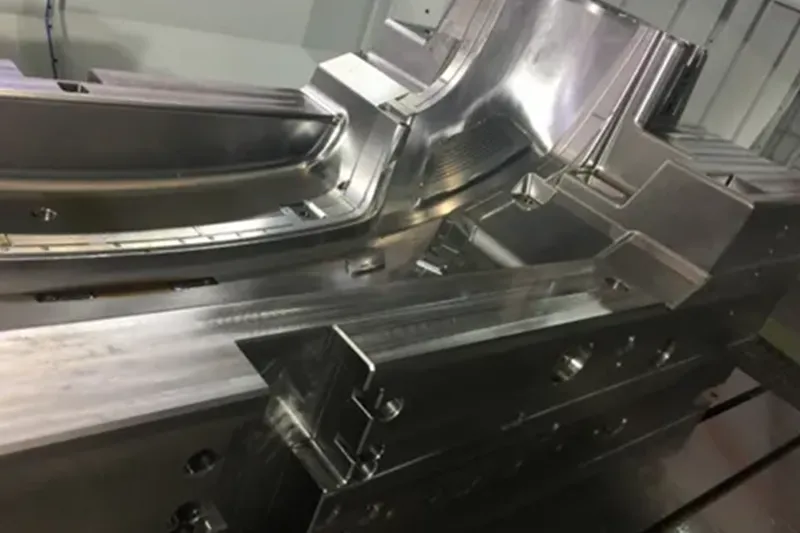

Designed for **extreme finishing accuracy and high-speed efficiency**. The fixed bridge structure provides maximum rigidity, ideal for high-precision molds and aerospace structural parts.

- Fixed bridge for maximum damping

- Table load capacity up to 30,000kg

Features Of Our CNC Gantry Machining Center

Ultra-Rigid Mehanite Cast Iron Foundation

Micron-Level Geometric Accuracy

Box-Way & Linear Guide Hybrid Optimization

Advanced Thermal Stability Control

The Precision of HIRUNG CNC Gantry Machining Centers

At HIRUNG, precision is our lifeline. We engineer high-performance tools that redefine "Made in China" through four core pillars of excellence:

1. Precision Manufacturing & Ultra-Rigid Assembly

Our foundation is Mehanite GC-275 cast iron, stress-relieved for lifetime stability. Featuring Class C3 double-nut ball screws and premium roller guides, we ensure structural alignment within 0.01mm/1000mm. Every critical interface is hand-scraped to guarantee the perfect flatness required for heavy-duty, vibration-free machining.

2. Industry-Leading Accuracy Testing

Every machine undergoes dual-stage verification using Renishaw Laser Interferometers and Wireless Ball Bar tests to calibrate full-travel pitch error and geometric squareness:

Positioning Accuracy: ≤ 0.010 mm (Full Travel)

Repeatability: ± 0.003 mm

Thermal Displacement: < 0.005 mm via Active Oil Cooling

Why Choose HIRUNG Gantry Centers?

Choosing HIRUNG means investing in uncompromising stability and global-standard efficiency. We don't just sell machines; we provide a high-performance production foundation:

Proven Global Reliability

Since 2015, over 33 countries (including high-precision markets like Sweden and Russia) have relied on HIRUNG. Our manufacturing standards exceed the domestic average, ensuring a 30% longer machine lifecycle.

Superior Heavy-Duty Performance

Built with Mehanite GC-275 cast iron and dual-drive Y-axis synchronization, our gantry centers handle table loads up to 30 tons while maintaining a positioning accuracy of ≤0.01mm.

Precision That Lasts

We guarantee micron-level repeatability (±0.003mm). By integrating active spindle oil cooling, we keep thermal displacement under 0.005mm, ensuring your first part is as precise as your last.

Lower TCO (Total Cost of Ownership)

Engineered for maintenance convenience, our machines feature modular components and high-durability wear parts, significantly reducing downtime and long-term service costs.

Application

Mold & Die

Aerospace

Medical instruments

Hear the Voices of Our Clients

Partner Brands in CNC Machines

FAQ

First, you should contact our salesperson.

Let us know the required machine tool model, detailed configuration requirements, etc. and the drawings of the parts you processed.

We will have professional engineers to provide you with a selection plan.

Then, we will provide you with a quotation and the information you need.

Next, we will sign the sales contract with you.

You can choose USD, EUR, or RMB as the settlement currency.

The payment methods are: T/T and L/C.

The general situation is: 30% production deposit, 70% to be paid before shipment.

Conventional models with a delivery cycle of no more than 30 days.

Special customized equipment within 180 days.

Some models are available in stock.

HIRUNG has been selling internationally since 2015, and we have a mature packaging solution. We have a complete set of mature solutions for loading containers, unloading containers, and landing machine tools, so you don’t have to worry about packaging safety. We use wooden pallets (or steel pallets)+vacuum packaging, as well as protective layers, to prevent water ingress, rust, corrosion, scratches, and other phenomena caused by machine tools during transportation.

Our common trade methods are: EXW/FOB/CIF.

We will adopt different trading methods according to different countries and regions.

For example:

Train transportation: We usually use EXW more frequently.

Ship transportation: There are many FOB terms, HIRUNG cnc machines has been sold internationally in 33 countries and regions worldwide since 2015. We have abundant transportation resources. If you need CIF to your port, we can also easily complete it for you.

In some countries, we can help you clear customs to your factory.

HIRUNG will provide the following documents for free according to your needs:

1: Passport of machine tool (e.g. inspection certificate)

Machine tool picture+nameplate picture+machine tool operation manual (sent randomly)

Pre acceptance agreement

CE inspection documents

2: Logistics documents

Packing list

Bill of lading (CIF terms apply)

Insurance policy (CIF terms apply)

Certificate of origin

If you need special documents, you can communicate with the salesperson.

If there is a local distributor, our distributor will assist you throughout the process.

If you are the end user and do not understand how to install machine tools, please do not worry.

You only need to do the following three things to easily use the machine tool:

1: Place the machine tool in a fixed position and use a leveling instrument to place the machine tool in a horizontal state;

2: Link necessary accessories (such as chip conveyor, water pump) and power plugs (we will mark them properly, you need to connect them according to the markings to see);

3: Connect the main power supply. Our machine tool is equipped with a power phase sequence protection device as standard. If the power phase sequence is incorrect, a red indicator will be displayed, and green indicates the correct phase sequence.

After completing the above three steps, you can start using the machine tool.

A: There are local dealers: the dealers will provide you with after-sales service support throughout the process.

B: You are the end user and there are no local distributors:

HIRUNG has always prioritized the stability of machine tools as its top priority. Among our users in 33 countries, 50% are directly purchased by end users. Therefore, the stability of machine tools is crucial.

If the machine tool is unstable, a large number of after-sales service personnel are needed. There are feedbacks from 9 years HIRUNG international user: HIRUNG is one of the most stable machine tools in the world!

If there is a problem with your machine:

Firstly, there is a fault code on the display screen of our machine tool, you will need to do as the following steps:

1: Based on the fault code, you can find the repair plan in our operation manual.

2:The electronic control system unit has corresponding function labels attached to each electronic control component. For example, the system prompts that the water pump is overloaded. You only need to open the electrical box, find the “water pump” label, and reset it to eliminate the fault code.

3: HIRUNG’s accumulated teaching file library for fault repair over the years (steps+pictures+text explanations).

As long as you send us pictures of your malfunction, we will immediately send you the corresponding repair teaching steps, even engineers without any repair experience can easily complete them.

On the nameplate of each machine tool, there is the contact information for after-sales service, email+phone (Whats APP+WeChat), and you can find us at any time.