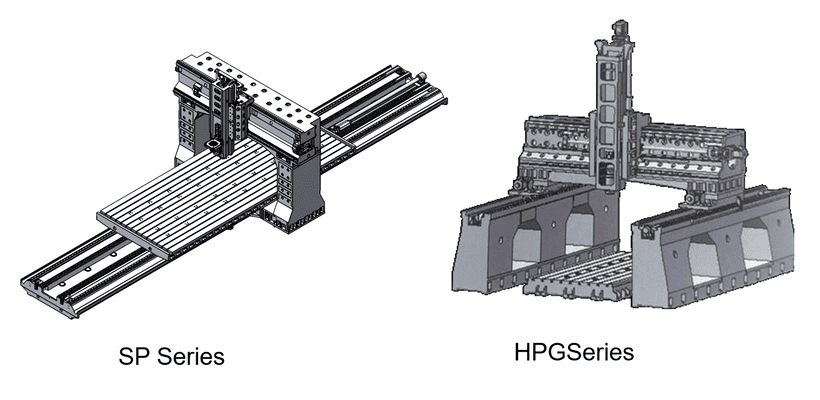

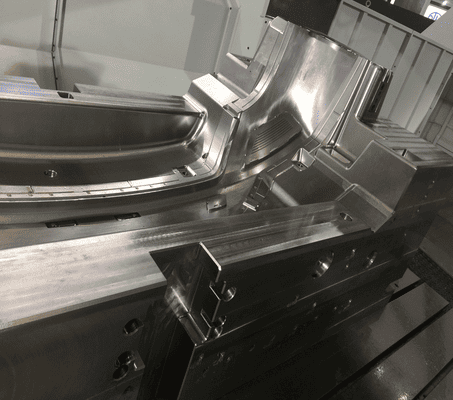

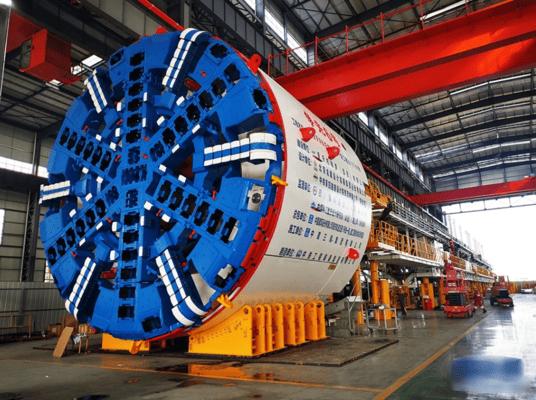

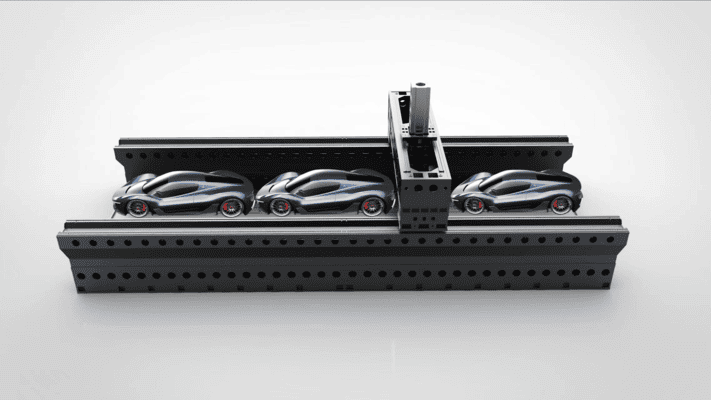

Large CNC gantry machining center equipment is a machine tool suitable for precision machining of large workpieces. Compared with traditional manual equipment, CNC gantry milling has the characteristics of high automation, high machining accuracy and high efficiency. It is widely used in aerospace, shipbuilding, automobile industry, wind power generation and mold manufacturing industries.

When we encounter large parts that need to be processed, we will think that we need an extra-large CNC gantry machine to complete this task.

So, how do we transport such a large machine from China to your country?

Don’t worry, HIRUNG has more than 10 years of equipment export experience. Below I will introduce to you how large machinery and equipment arrive at your factory from China。

Table of Contents

ToggleSolution 1: CNC gantry machining center with a length of less than 11.5 meters and a width of less than 4 meters.

We recommend that the whole machine be transported to your port by container. The container we use is 40FR, which can reach your factory in one go.

Note: When transporting by road, it is necessary to report to the transportation department in advance: overweight, overwidth, and overheight.

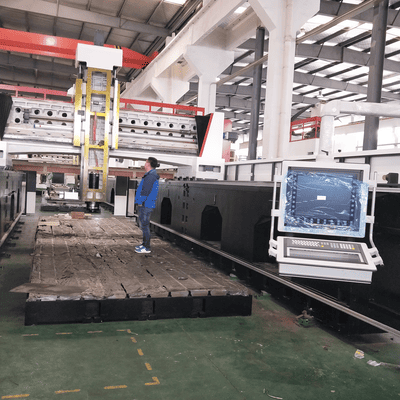

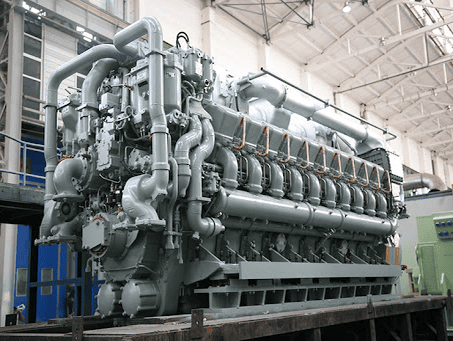

*The above picture shows HIRUNG transporting a SP4027 CNC gantry machining center by sea. The weight of the machine tool is 40 tons*

Solution 2: Super-large CNC gantry machining center

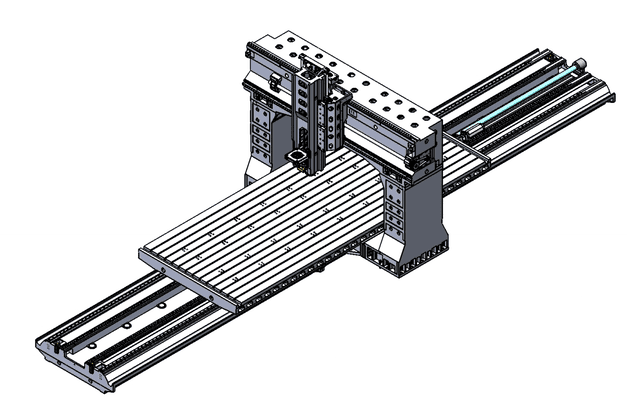

Here, super-large CNC gantry refers to machines with a mechanical length of more than 11.5 meters and a width of more than 4 meters (usually the X-axis is greater than or equal to 5 meters and the Y-axis is greater than or equal to 3 meters). We need to use a split transportation method.

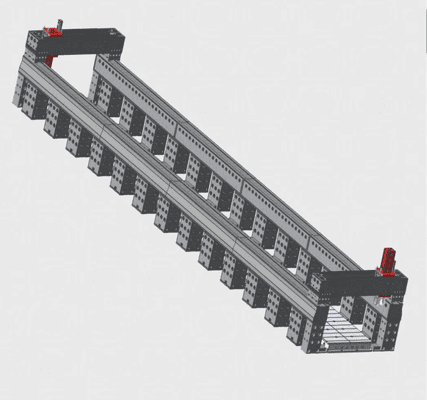

This means that after the machine tool is debugged at the HIRUNG factory, we split it and pack it, with the base and workbench as a whole package, the column and the beam as a whole package, and the rest of the accessories (housing, electrical, accessories) as a whole package. It is transported separately by more than 2 containers, and the weight of each container is controlled within the range of about 26 tons (26 tons is the load requirement of the container).

Don’t worry, we generally design the length of the base and workbench to be 6 meters long, and each section can be separated separately.

In the first 60 days of delivering the equipment, we will give you a detailed foundation construction requirement drawing. When the machine arrives at your factory, we will arrange engineers to go to your factory for installation and commissioning as soon as possible, all for free. You only need to arrange relevant cranes and some ordinary workers to assist us.

If you are interested in the installation process, you can check our installation video. This video is a 20-day workload. We shorten it to 2 minutes for your convenience.

Customization and Capabilities

HIRUNG excels in delivering tailored solutions for even the largest CNC gantry machining centers. Our capabilities include:

- Machines with a maximum X-axis length of 60 meters and X-axis travel of 6 meters.

- Non-standard configurations, such as 5-axis, 6-axis, and 10-axis CNC gantry machining centers.

No matter the size or complexity of your workpiece, HIRUNG can design a solution to meet your needs.

Conclusion

Book a technical demonstration now and experience the dual revolution of precision and efficiency!

- WeChat/WhatsApp: +8613826425988

- Official Website: www.hirung.com