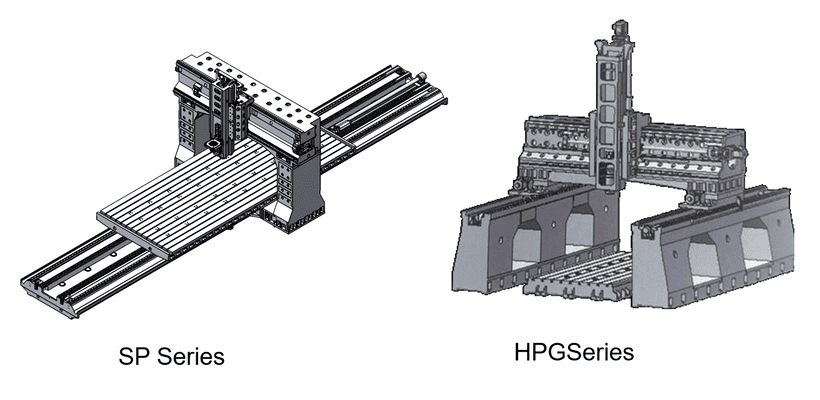

When selecting a gantry structure for applications involving massive components where rigidity is paramount, the HPG (High-Performance Gantry) series is definitively the superior choice over the SP (Standard-Profile) series. The HPG’s architecture, featuring an elevated Y-axis and dual-drive X-axes, is specifically engineered to counteract moment loads and minimize deflection, ensuring maximum structural stiffness and precision under heavy payloads. While the SP series offers a cost-effective and compact solution, it lacks the inherent rigidity needed for high-tolerance machining or handling of large, heavy workpieces. This article provides an in-depth analysis to guide engineers and system integrators in making the optimal selection based on application-specific demands.

Table of Contents

- What Defines Gantry Structure Rigidity and Why is it Crucial?

- Unpacking the HPG (High-Performance Gantry) Series

- Analyzing the SP (Standard-Profile) Series

- Head-to-Head Comparison: HPG vs. SP for Rigidity

- How to Select the Right Gantry for Your Application

- Conclusion: Making the Final Decision for Ultimate Rigidity

What Defines Gantry Structure Rigidity and Why is it Crucial?

Before comparing gantry models, it’s essential to understand what gantry rigidity truly means and its impact on performance. Rigidity, or stiffness, is a mechanical structure’s ability to resist deformation (deflection) when subjected to external forces. In the context of a gantry system, these forces come from the payload’s weight, acceleration and deceleration dynamics, and process forces from tools like a milling spindle or laser head. A lack of rigidity directly compromises the system’s accuracy, repeatability, and the quality of the finished product, leading to dimensional errors, poor surface finishes, and reduced tool life.

We can break down rigidity into two primary types. Static rigidity refers to the system’s resistance to deflection under a constant load, such as the weight of the gantry’s own cross-beam and the payload when stationary. Dynamic rigidity, which is often more critical, is the structure’s ability to resist deformation and vibration during movement—high-speed traverses, rapid acceleration changes, and directional shifts. For massive components, poor dynamic rigidity results in overshooting, oscillation, and an inability to maintain a precise tool path, rendering the system ineffective for high-tolerance work.

Unpacking the HPG (High-Performance Gantry) Series

The HPG series represents the pinnacle of gantry design for applications demanding the highest levels of structural integrity. Its design philosophy prioritizes stiffness and dynamic performance above all else, making it the default choice for processing large, heavy, or complex parts where precision cannot be compromised.

Core Architectural Principles of HPG Systems

The defining characteristic of an HPG system is its elevated Y-axis beam. Unlike simpler designs where all axes might be on a single plane, the HPG’s main moving bridge (the Y-axis) is raised significantly above the two parallel base axes (the X-axes). This “bridge-style” construction is supported on robust vertical risers. Furthermore, HPG gantries almost universally employ a dual-drive system on the X-axis, with synchronized motors (typically linear motors or ballscrew systems with master-slave control) on both sides of the base. This synchronized drive is crucial for preventing “racking” or crabbing, where one side of the gantry lags behind the other, inducing twist and inaccuracy.

This architecture is inherently more stable and rigid. The separation between the parallel X-axis guides creates a wide, stable foundation. The elevated Y-axis, combined with a stiff, boxy cross-section, effectively manages forces in all directions (Fx, Fy, Fz) as well as rotational moments (Mx, My, Mz). The materials used are also typically optimized for a high stiffness-to-weight ratio, such as stress-relieved steel fabrications, granite, or specialized aluminum extrusions, to minimize inertia while maximizing rigidity.

Why HPG Gantries Excel with Massive Components

The HPG design directly addresses the challenges posed by massive components. The primary advantage is its superior ability to handle high moment loads. When a heavy tool or workpiece is positioned off-center on the Y-axis, it creates a torsional moment that tries to twist the entire structure. The HPG’s wide stance and stiff, elevated cross-beam provide exceptional resistance to this twisting. This ensures that the tool center point remains precisely where it’s commanded, even under high dynamic loads and with a high center of gravity.

Furthermore, the dual-drive system ensures smooth, powerful, and accurate motion across the entire work envelope, eliminating the risk of binding or skewing that can plague single-drive systems under heavy load. This allows for higher acceleration and deceleration rates without sacrificing precision. For applications like 5-axis machining of large aerospace structures or automotive molds, this dynamic stiffness is non-negotiable, as it directly translates to faster cycle times and better surface finishes.

Common Applications and Industries for HPG

HPG gantries are the workhorses of industries where scale and precision intersect. Key applications include:

- Aerospace and Defense: Machining large monolithic structures, fuselage sections, wing spars, and composite trimming.

- Automotive: Milling large stamping dies and molds, large-format CMM inspection, and laser welding of car bodies.

- Large-Format Additive Manufacturing: Supporting heavy deposition heads for Wire Arc Additive Manufacturing (WAAM) or large-scale Fused Deposition Modeling (FDM).

- Energy Sector: Machining components for wind turbines, such as blade roots or hub components.

- Heavy-Duty Laser and Waterjet Cutting: Processing thick steel plates or large composite panels where maintaining nozzle standoff distance is critical for cut quality.

Analyzing the SP (Standard-Profile) Series

The SP series, which can stand for Standard-Profile or Single-Plane, represents a more common and cost-effective approach to gantry design. These systems are engineered for a broad range of applications where the extreme rigidity and payload capacity of an HPG are not required.

Defining the SP Gantry Architecture

The SP gantry architecture is characterized by its lower profile and simpler construction. Often, the Y-axis beam moves directly on top of the X-axis guides, resulting in a more co-planar or “flat” arrangement. This significantly reduces the overall height and complexity of the machine. While some larger SP systems may use a dual-drive on the X-axis, it is also common to find smaller or lighter-duty versions with a single X-axis drive connected to the gantry via a linking shaft or, in some cases, driving the gantry from one side.

The primary design goal for SP systems is to provide reliable XY motion in a compact and economical package. The cross-section of the moving beam is typically less substantial than that of an HPG, and the overall mass is lower. This design is perfectly adequate for many applications but introduces clear limitations when dealing with heavy or off-center loads.

Strengths and Inherent Limitations

The main strength of the SP series lies in its cost-effectiveness and smaller footprint. The simpler design requires less material and less complex manufacturing, leading to a lower initial investment. The reduced height makes it easier to integrate into facilities with ceiling height restrictions and can improve operator access. They are also generally easier to assemble and maintain.

However, this simplicity comes with inherent limitations in rigidity. The lower-profile design has a much smaller effective stance against moment loads. An off-center payload will induce significantly more deflection and twist compared to an HPG. In single-drive variants, the system is highly susceptible to racking, especially over wider spans. Consequently, SP gantries are limited to lower payloads, lower acceleration rates, and applications where the process forces are minimal. Pushing an SP gantry beyond its design limits will result in vibration, poor accuracy, and premature wear on the guide and drive components.

Ideal Use Cases for SP Gantries

SP gantries are highly effective and widely used in applications where rigidity requirements are moderate. Ideal use cases include:

- Light-Duty Pick-and-Place: Automated sorting, packaging, and assembly of small, lightweight products.

- Dispensing and Coating: Applying adhesives, sealants, or coatings where the tool weight and process forces are low.

- Laser Engraving and Light Cutting: Working on thin materials like sheet metal, acrylic, or wood.

- Automated Optical Inspection (AOI): Carrying lightweight cameras and sensors for quality control.

- Plotting and Vinyl Cutting: Applications with virtually zero process forces.

Head-to-Head Comparison: HPG vs. SP for Rigidity

To make the differences clear, this table provides a direct comparison of the HPG and SP series across key performance metrics, with a focus on applications involving massive components.

| Feature | HPG (High-Performance Gantry) Series | SP (Standard-Profile) Gantry Series |

|---|---|---|

| Structural Rigidity | Exceptional. The elevated bridge and wide stance provide maximum resistance to bending and torsion. | Moderate. Prone to deflection and twisting under heavy or off-center loads. |

| Moment Load Capacity | Very High. Specifically designed to counteract moments from heavy, off-center payloads and high process forces. | Low to Medium. The primary limiting factor for heavy-duty applications. |

| Dynamic Performance | Excellent. Capable of high acceleration/deceleration with minimal vibration or overshoot due to high stiffness. | Fair to Good. Dynamics must be de-rated for heavier payloads to avoid oscillation and maintain accuracy. |

| Payload Capacity | Suited for massive components, heavy spindles, and complex multi-axis tool heads (hundreds to thousands of kg). | Best for light to medium payloads (typically under 50-100 kg, depending on size). |

| Footprint & Height | Large and tall, requiring significant floor space and vertical clearance. | Compact and low-profile, easier to integrate into existing spaces. |

| Cost (Initial Investment) | High. More complex design, more material, and precision assembly increase costs significantly. | Low to Medium. A more economical choice for suitable applications. |

| Best For… | High-speed machining, 5-axis processing, handling massive/heavy components, applications where ultimate precision is key. | Pick-and-place, inspection, dispensing, laser engraving, and light-duty cutting or assembly. |

How to Select the Right Gantry for Your Application

The choice between an HPG and an SP gantry is not merely a matter of which is “better,” but which is the *right tool for the job*. Over-specifying a gantry (using an HPG where an SP would suffice) leads to unnecessary capital expenditure, while under-specifying (using an SP for a heavy-duty task) results in poor performance, low-quality output, and potential machine failure.

Key Questions to Ask Before You Decide

To guide your decision, your engineering team must answer these critical questions about the application:

- What is the mass and center of gravity of the payload? This includes the tool, any sub-axes (like a Z or rotary axis), and the workpiece if it is carried by the gantry. This is the single most important factor.

- What are the process forces? Is it a non-contact inspection (zero force) or aggressive milling of titanium (high force)?

- What are the dynamic requirements? What are the target acceleration, velocity, and cycle times? High dynamics demand high rigidity.

- What are the required accuracy, repeatability, and path-following specifications? Tighter tolerances generally push the selection towards an HPG.

- What is the size of the work envelope? Racking becomes a greater concern on wider gantries, favoring the dual-drive HPG design.

- What are the physical and environmental constraints? Consider floor space, ceiling height, and thermal stability requirements.

- What is the total project budget? Be realistic about the cost implications. An HPG is a significant investment, but the cost of failure from an under-specified system can be even greater.

A Decision-Making Framework for Gantry Selection

Use this simple framework as a final check:

- If your application involves heavy payloads (>100 kg), high process forces, a high center of gravity, high dynamics, AND requires tight tolerances, the choice is unequivocally the HPG series. Do not compromise.

- If your application involves light payloads, low process forces, a compact work area, and moderate accuracy needs where budget and footprint are primary concerns, the SP series is the logical and cost-effective choice.

- For applications in the “gray area” (e.g., a medium-weight payload with moderate dynamics), a thorough analysis using Finite Element Analysis (FEA) and consultation with gantry manufacturers is highly recommended. It may be possible to use a heavily-optioned SP system or a smaller HPG system.

Conclusion: Making the Final Decision for Ultimate Rigidity

The selection between HPG and SP series gantry structures is a critical engineering decision that hinges on a clear-eyed assessment of the application’s demands. For handling and processing massive components where structural rigidity is the cornerstone of performance, the HPG series stands alone. Its robust, elevated bridge architecture and dual-drive system are purpose-built to deliver the stiffness, moment load capacity, and dynamic accuracy required for the most demanding tasks in aerospace, automotive, and heavy manufacturing.

Conversely, the SP series provides an invaluable solution for a vast array of less demanding applications, offering excellent performance in a cost-effective and compact package. Understanding the fundamental architectural differences—and their direct implications for rigidity—empowers engineers to invest wisely, avoiding the dual pitfalls of over-specification and under-performance. By prioritizing a thorough analysis of payload, forces, and required precision, you can confidently select the gantry system that will serve as a reliable and productive foundation for your automation project for years to come.

HPG vs SP gantry, gantry structure, massive component rigidity, selecting gantry structure, HPG gantry, SP gantry, high rigidity gantry system, gantry for large components, what is gantry rigidity, HPG gantry architecture, SP gantry limitations, gantry selection guide, moment load capacity, gantry for aerospace machining