Effectively machining high-hardness materials like hardened tool steels, titanium alloys, and Inconel requires more than just a standard Vertical Machining Center (VMC). The immense cutting forces and thermal stress demand a machine built with specific engineering principles at its core. Success hinges on two critical, interconnected elements: a specialized spindle capable of delivering high torque at appropriate speeds and an exceptionally rigid machine structure that can absorb and dampen vibration. VMCs that excel in this arena, such as those from HIRUNG, feature direct-drive spindles for superior torque and thermal stability, coupled with robust, wide-span box-type column designs and roller linear guideways to ensure unwavering rigidity and precision under extreme loads.

What Are the Challenges of Machining High-Hardness Materials?

Working with materials rated at HRC 50 and above introduces a set of intense physical challenges that can overwhelm standard CNC machines. The primary obstacle is the sheer cutting force required to shear the material. These forces translate directly into extreme pressure on the cutting tool, spindle bearings, and the entire machine frame. Without a machine designed to withstand these loads, the result is detrimental vibration, also known as chatter.

Chatter is the enemy of precision. It leads to poor surface finishes, compromises dimensional accuracy, and dramatically accelerates tool wear, causing frequent tool changes and increased operational costs. Furthermore, the friction generated during hard milling creates immense heat. This thermal energy can lead to thermal expansion in the spindle and machine frame, causing a loss of accuracy over time. It can also damage the cutting tool and negatively affect the metallurgical properties of the workpiece surface. Effectively managing both vibration and heat is non-negotiable for successful hard machining.

The Spindle Solution: Engineering for Torque and Stability

The spindle is the heart of any milling operation, and for high-hardness materials, its design is a defining factor for success. A spindle’s performance is not merely about maximum speed (RPM); it’s about the ability to deliver consistent power and torque exactly where it’s needed in the machining process.

Why High RPM Isn’t Always the Answer: The Torque Dilemma

While high-speed machining (HSM) is effective for softer materials like aluminum, hard milling often requires a different approach. Cutting hardened steel or titanium alloys efficiently necessitates larger-diameter tools running at lower RPMs to manage heat and tool life. In this range, **high torque** is paramount. Belt-driven or geared spindles, common in general-purpose machines, often struggle to deliver peak torque at lower speeds. They can suffer from belt slippage, gear backlash, and vibration, all of which are amplified under the strain of hard milling.

The core issue is that these traditional transmission systems introduce points of failure and power loss between the motor and the tool. The machine might have a powerful motor, but if that power can’t be translated into rotational force (torque) at the cutting edge, it’s wasted.

How HIRUNG’s Direct-Drive Spindle Masters Hard Milling

This is where the engineering of a direct-drive spindle, a hallmark of HIRUNG VMCs, provides a distinct advantage. In a direct-drive system, the motor is integrated directly with the spindle shaft. This design eliminates belts, gears, and other intermediate components, leading to several key benefits:

- Maximum Torque at Low RPMs: By directly coupling the motor to the spindle, nearly 100% of the motor’s torque is available across a wider speed range, especially at the lower RPMs critical for hard milling. This allows the machine to power through tough cuts without stalling or chatter.

- Superior Acceleration and Deceleration: The reduced inertia of a direct-drive system allows for faster and more precise spindle speed changes, which is crucial for complex 3D contouring found in mold making.

- Reduced Vibration: With fewer moving parts, the spindle assembly generates significantly less inherent vibration, resulting in smoother cuts and better surface finishes.

Managing the Heat: The Critical Role of Spindle Cooling

The intense power required for hard milling generates significant heat within the spindle motor and bearings. Unchecked, this heat leads to **thermal growth**, where the spindle physically expands, altering the tool’s Z-axis position and compromising accuracy. HIRUNG machines address this with sophisticated spindle cooling systems. A liquid cooling circuit circulates fluid through channels in the spindle housing, actively drawing heat away from critical components like the motor and bearings. This ensures *thermal stability*, keeping the spindle at a consistent operating temperature and guaranteeing precision from the start of a job to the end, even during long, demanding machining cycles.

The Structural Backbone: Designing for Unyielding Rigidity

A powerful spindle is only effective if it’s mounted on a structure that can support it. The machine’s frame—its base, column, and saddle—is the foundation of its performance. For high-hardness materials, *rigidity is not a feature; it is a prerequisite*. The structure must be able to absorb the massive cutting forces without flexing or vibrating.

Where Conventional VMC Frames Fall Short

Many standard VMCs utilize a simple C-frame design with a relatively narrow base and column. While adequate for light-duty work, this construction can act like a tuning fork when subjected to the heavy, intermittent loads of hard milling. The forces cause microscopic twisting and bending in the frame, which manifests as chatter at the tool tip. This structural flexing is a primary source of inaccuracy and poor tool life in demanding applications.

The HIRUNG Advantage: A Foundation of Box-Type Construction

HIRUNG VMCs are engineered with a focus on maximum structural stiffness. This is achieved through key design choices:

- Wide-Span Base and Column: The machine base is designed with an extra-wide stance, providing a more stable foundation. The vertical column, which supports the spindle head, employs a large-span, box-type internal structure. This heavily ribbed, enclosed design is inherently more resistant to torsional (twisting) and bending forces than simpler hollow or open-back columns.

- Meehanite Cast Iron: The use of high-quality Meehanite cast iron for all major structural components provides excellent vibration damping characteristics. This material naturally absorbs cutting vibrations rather than transmitting them through the machine.

This robust construction ensures that the cutting forces are directed down into the machine’s foundation and absorbed, not reflected back as vibration. This keeps the tool tip precisely where the CNC program commands it to be, even under the most aggressive cutting conditions.

Enhancing Stability with Roller Linear Guideways

The stability of the moving axes is just as important as the static frame. While many VMCs use ball-type linear guideways, HIRUNG machines utilize **high-precision roller linear guideways** on all three axes. The difference is significant:

| Feature | Ball-Type Guideways | Roller-Type Guideways (HIRUNG) |

| Contact Type | Point contact | Line contact |

| Load Capacity | Lower | Significantly higher |

| Rigidity | Good | Excellent |

| Deformation Under Load | Higher | Lower |

The line contact of roller guideways provides a much larger contact area than the point contact of ball bearings. This allows them to handle substantially heavier loads with minimal deformation, providing superior rigidity for the X, Y, and Z axes. This means that when the table is moving a heavy workpiece or the spindle head is performing an aggressive plunge, the axes do not deflect, ensuring consistent accuracy.

A Holistic Approach: Integrating Spindle and Structure

The true excellence of a machine designed for high-hardness materials lies in the synergy between its spindle and its structure. It is an integrated system where each component is designed to complement the others in the fight against vibration and thermal instability.

What Is Vibration Damping and Why Is It Paramount?

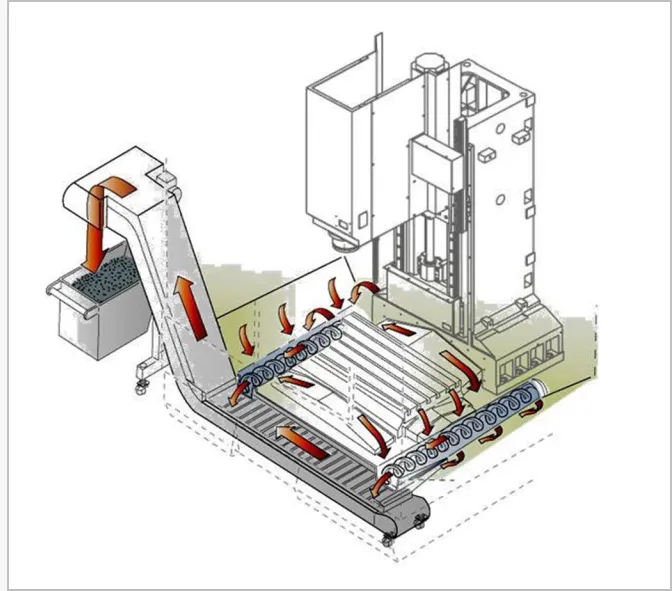

Vibration damping is a machine’s inherent ability to absorb and dissipate vibrational energy. In a HIRUNG VMC, this is a multi-faceted achievement. It begins with the mass and material of the **Meehanite cast iron frame**. It continues with the **box-type column** that resists flexing and the **roller guideways** that prevent deflection in the moving axes. Finally, the **direct-drive spindle** contributes by generating less vibration in the first place. This holistic design creates a system that is exceptionally resistant to chatter, allowing for deeper cuts, higher material removal rates, and dramatically improved tool life.

Achieving Superior Surface Finishes on Demanding Materials

A superior surface finish is the direct result of a stable and precise cutting process. When the spindle runs smoothly and the structure is completely rigid, the cutting tool moves along its programmed path without deviation. The combination of a low-vibration direct-drive spindle and an unyielding machine frame on HIRUNG VMCs ensures that the tool’s cutting edge can produce a clean, consistent finish, free from the tell-tale marks of chatter. This often reduces or eliminates the need for secondary finishing operations, saving valuable time and resources.

Where HIRUNG VMCs Deliver: Proven Applications

The specialized design of HIRUNG VMCs makes them ideal for industries where machining hard materials to tight tolerances is a daily requirement. The robust engineering translates directly into tangible benefits in some of the most demanding manufacturing sectors.

High-Precision Mold and Die Manufacturing

Mold makers frequently work with pre-hardened tool steels like P20, H13, and S7. Machining intricate cavities, cores, and lifters in these materials requires a machine that can maintain accuracy over long hours of complex 3D contouring. The thermal stability of HIRUNG’s cooled, direct-drive spindle prevents Z-axis drift, while the structural rigidity ensures that fine details and sharp corners are machined without deflection, resulting in a perfect part that requires minimal hand polishing.

Complex Aerospace and Medical Components

Industries like aerospace and medical device manufacturing rely on exotic alloys such as titanium, Inconel, and cobalt-chrome for their high strength-to-weight ratio and temperature resistance. These materials are notoriously difficult to cut. The high-torque performance of HIRUNG’s spindle, combined with the machine’s ability to damp vibration, makes it possible to machine these materials efficiently. This capability is essential for producing everything from turbine blades and structural airframe components to custom surgical implants, where part failure is not an option and precision is a matter of safety and function.