The five most common types of CNC machines essential to modern manufacturing are CNC Mills, CNC Lathes (or Turning Centers), CNC Routers, CNC Grinders, and Electrical Discharge Machines (EDM). These automated tools form the backbone of precision engineering, operating on the principle of Computer Numerical Control (CNC), where pre-programmed computer software dictates the movement of factory tools and machinery. This process, primarily known as subtractive manufacturing, involves precisely removing material from a solid block (a blank or workpiece) to create a final, highly accurate part. From aerospace components to intricate medical devices, understanding which machine to use is fundamental to achieving the desired outcome in terms of complexity, material, and precision.

What is CNC Machining? A Quick Refresher

At its core, Computer Numerical Control (CNC) machining is a manufacturing process that automates the control, movement, and precision of machine tools through computer software. Before CNC, machines were operated manually, requiring constant operator attention and skill, which could lead to inconsistencies. CNC technology revolutionized the industry by translating a digital design—created with Computer-Aided Design (CAD) software—into a set of specific instructions, or G-code, that a machine can execute flawlessly and repeatedly. This ensures every part produced is identical and meets exact specifications.

The Role of G-Code and CAM Software

The bridge between a digital model and a physical part is built by Computer-Aided Manufacturing (CAM) software. CAM software takes a CAD file and generates a machine-readable program known as G-code. This code is the universal language of CNC machines, dictating every action: where the tool should move, how fast it should travel, the spindle speed, when to turn coolant on or off, and much more. For example, a command might look like `G01 X50 Y25 F200`, which tells the machine to make a linear move to the coordinates (X=50, Y=25) at a feed rate of 200 mm/min. The precision of the final part is entirely dependent on the quality of this code and the machine’s ability to execute it.

Subtractive vs. Additive Manufacturing

CNC machining is the quintessential subtractive manufacturing process. Imagine a sculptor starting with a block of marble and chipping away material to reveal a statue; CNC machining does the same, but with materials like metal, plastic, or wood, using cutting tools instead of a chisel. This is in direct contrast to additive manufacturing, such as 3D printing, where a part is built layer by layer from nothing. While additive methods are excellent for rapid prototyping and complex internal geometries, subtractive CNC machining remains unparalleled for its ability to produce parts with superior strength, tight tolerances, and excellent surface finishes from a wide range of production-grade materials.

The 5 Most Common Types of CNC Machines

While many specialized CNC machines exist, five types form the foundation of most machine shops and manufacturing facilities. Each is designed for a specific type of operation, material, and geometric outcome. At Hirung, our expertise spans across these core technologies, allowing us to select the perfect process for each unique project.

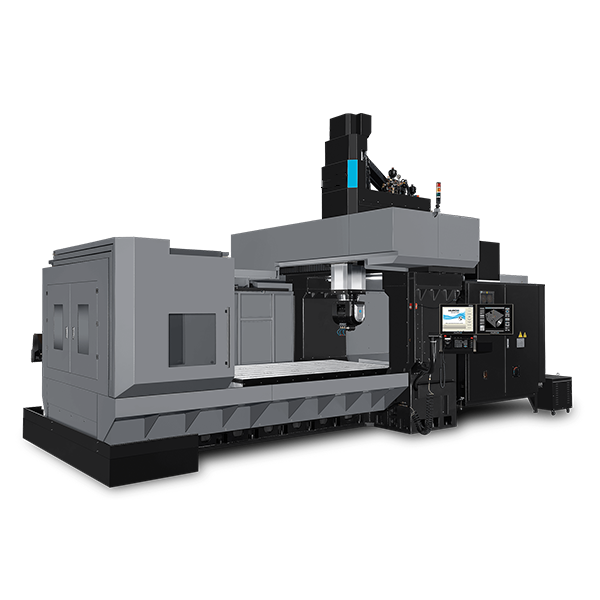

1. CNC Milling Machines

A CNC milling machine is one of the most versatile and widely used CNC machines. The core principle involves a rotating multi-point cutting tool that moves along multiple axes to remove material from a stationary workpiece. The workpiece is secured to a machine bed, and the computer directs the cutting tool to create various features, such as flat surfaces, pockets, slots, and complex 3D contours.

A key differentiator for CNC mills is their axes of motion.

- 3-Axis Mills: The most common type, moving the tool along the X, Y, and Z linear axes. Ideal for parts with simpler geometries.

- 4-Axis Mills: Adds a rotational axis (the A-axis), allowing the workpiece to be rotated during cutting. This enables machining on the sides of a part without needing a new setup.

- 5-Axis Mills: The pinnacle of milling technology, featuring three linear axes (X, Y, Z) and two rotational axes (A and B/C). This allows the tool to approach the workpiece from any direction, making it possible to create exceptionally complex geometries, undercuts, and organic shapes in a single setup. This capability is critical in industries like aerospace and medical, where intricate and precise components are standard.

CNC milling is suitable for a vast range of materials, including aluminum, stainless steel, titanium, plastics, and composites.

2. CNC Lathes (Turning Centers)

Where a mill uses a rotating tool on a stationary part, a CNC lathe (or turning center) does the opposite. It holds and rotates the workpiece at high speed while a stationary single-point cutting tool moves along its surface to remove material. This makes lathes ideal for creating cylindrical, conical, or spherical parts. The cutting tool is mounted on a turret, which can hold multiple tools and be indexed automatically by the program.

The primary operations performed on a lathe include turning (reducing diameter), facing (creating a flat end), grooving, threading, and drilling along the center axis. Modern CNC turning centers often incorporate live tooling, which are powered, rotating tools that can perform secondary milling, drilling, or tapping operations on the part without removing it from the lathe. This multi-tasking ability dramatically increases efficiency and accuracy, transforming a simple lathe into a powerful all-in-one machining solution for complex rotational parts like shafts, pins, and custom fittings.

3. CNC Routers

Structurally, a CNC router is similar to a CNC mill, as it also uses a rotating tool to cut a stationary workpiece. However, routers are typically designed for “softer” materials and are often much larger in size. While a mill is built for the rigidity required to cut tough metals like steel and titanium, a router excels at machining materials like wood, plastic, foam, composites, and soft metals like aluminum.

CNC routers are the workhorses of industries like cabinet making, sign making, and woodworking, where they can carve intricate designs, cut large sheets of material, and produce detailed 3D reliefs. They operate on a gantry system, where the spindle moves over a large, flat machine bed. While not typically used for the high-precision, tight-tolerance work of a CNC mill, they are invaluable for large-format cutting and creative applications.

4. CNC Grinding Machines

When a project requires an extremely high level of precision and an exceptionally smooth surface finish, a CNC grinding machine is the tool of choice. Instead of a cutting tool with teeth, a grinder uses a rotating abrasive wheel to achieve a fine, controlled removal of material. This process is less about bulk material removal and more about finishing a part that has already been machined to near its final size.

CNC grinders are essential for achieving ultra-tight tolerances—dimensions that are accurate to within a few microns (thousandths of a millimeter). They are commonly used to finish critical components like bearing races, transmission shafts, and precision gauges. The CNC control allows for precise management of the grinding wheel’s position, speed, and feed rate, ensuring consistent and flawless surface quality that is impossible to achieve with other machining methods.

5. Electrical Discharge Machines (EDM)

Electrical Discharge Machining (EDM) is a non-traditional machining process that uses electrical sparks (discharges) to erode material from a workpiece. It is used for materials that are electrically conductive, particularly very hard metals like hardened tool steel or titanium, which are difficult or impossible to machine with traditional tools. The process involves an electrode and the workpiece submerged in a dielectric fluid. A rapidly recurring current discharge between the two creates intense heat, melting and vaporizing microscopic particles of the material without any physical contact.

There are two main types of EDM:

- Wire EDM: Uses a thin, continuously fed wire as the electrode to make precise cuts, similar to a bandsaw. It is perfect for creating punches, dies, and intricate profiles.

- Sinker (or Ram) EDM: Uses a custom-shaped electrode (often made of graphite or copper) that is “sunk” into the workpiece, creating a cavity that is the inverse of the electrode’s shape. This is ideal for mold making and creating complex features.

Comparison of Common CNC Machine Types

To help visualize the differences, here is a table summarizing the key characteristics of each machine.

| Machine Type | Core Process | Primary Materials | Common Applications |

|---|---|---|---|

| CNC Mill | Rotating tool removes material from a stationary part. | Metals (Aluminum, Steel, Titanium), Plastics | Engine blocks, molds, complex 3D parts, aerospace components. |

| CNC Lathe | Rotating part is shaped by a stationary tool. | Metals, Plastics | Shafts, pins, screws, nozzles, cylindrical parts. |

| CNC Router | Rotating tool on a gantry system cuts large, soft materials. | Wood, Plastic, Foam, Composites, Soft Metals | Signage, furniture, prototypes, large-format carving. |

| CNC Grinder | Abrasive wheel provides high-precision surface finishing. | Hardened Metals | Bearings, gauges, shafts, parts requiring tight tolerances. |

| EDM | Electrical sparks erode conductive material without contact. | Hardened Steel, Titanium, Conductive Materials | Tool and die making, injection molds, complex internal shapes. |

How to Choose the Right CNC Machine for Your Project

Selecting the appropriate CNC machine is a critical decision that directly impacts the quality, cost, and lead time of your project. As a leading CNC machining supplier, we guide our clients through this process by evaluating several key factors.

Consider Your Material

The first question is always: what material are you using? Hard metals like tool steel or titanium may require the power of a robust CNC mill or the specialized process of EDM. Softer materials like wood or plastics are perfect for a CNC router. The material’s properties—its hardness, thermal stability, and machinability—will dictate which machine and which cutting tools are most effective.

Analyze Part Geometry and Complexity

The shape of your part is the next major consideration. Is it primarily cylindrical? A CNC lathe is the most efficient choice. Is it a prismatic part with pockets, holes, and complex surfaces? A 3, 4, or 5-axis CNC mill will be necessary. For parts with extremely intricate internal features or sharp internal corners that a cutting tool cannot create, Wire EDM may be the only viable option. The complexity dictates the required axes of motion and the type of machining operation.

Evaluate Required Tolerances and Surface Finish

What level of precision does your part demand? For general components, standard milling or turning may suffice. However, if your part requires tolerances measured in microns or a mirror-like surface finish, then CNC grinding is a necessary secondary operation. Communicating your exact tolerance and finish requirements is crucial for ensuring the final part meets its functional and aesthetic needs.

The Future of CNC Machining & Hirung’s Commitment

The world of CNC machining is constantly evolving. Innovations in AI-driven toolpath optimization, automation with robotics, and hybrid machines that combine subtractive and additive processes are pushing the boundaries of what is possible. These advancements lead to greater efficiency, higher precision, and the ability to manufacture “impossible” parts.

At Hirung, we are committed to staying at the forefront of this technological wave. Our investment in state-of-the-art equipment and the continuous training of our expert engineers ensure we can tackle the most demanding projects. We understand that each of these CNC machine types is a specialized tool, and true mastery lies in knowing precisely which one to use for the job.

Whether your project requires the intricate detail of 5-axis milling, the rotational efficiency of a CNC lathe, or the ultra-fine finish of precision grinding, partnering with an expert is key to success. We are not just a supplier; we are your manufacturing partner, dedicated to turning your designs into reality with unmatched quality and precision. Contact us today to discuss your project requirements and discover how our advanced CNC capabilities can work for you.