The primary difference between 3-axis and 5-axis CNC machining lies in the movement capabilities of the cutting tool and the workpiece. In 3-axis machining, the cutting tool moves along three linear axes (X, Y, and Z) to remove material, which is ideal for simpler, prismatic parts. In contrast, 5-axis machining adds two rotational axes to the three linear ones, allowing the cutting tool to approach the workpiece from virtually any angle. This enables the creation of highly complex and contoured surfaces in a single setup, significantly improving efficiency and precision for intricate designs.

In the world of precision manufacturing, Computer Numerical Control (CNC) machining stands as a cornerstone technology. It uses computer-guided controls to operate machine tools, shaping raw materials into finished parts with incredible accuracy. However, not all CNC machines are created equal. The most significant distinction often comes down to the number of axes a machine can utilize. Understanding the fundamental differences, capabilities, and applications of 3-axis and 5-axis CNC machining is crucial for engineers, designers, and project managers to optimize their manufacturing strategy for cost, speed, and quality. This guide provides a comprehensive comparison to help you determine which process is the right fit for your project.

Table of Contents

- What is 3-Axis CNC Machining? A Foundational Approach

- What is 5-Axis CNC Machining? The Advanced Solution

- Head-to-Head Comparison: 3-Axis vs. 5-Axis

- How to Choose Between 3-Axis and 5-Axis Machining? Key Decision Factors

- The Future is Complex: Why 5-Axis is Gaining Ground

- Conclusion: Making the Right Choice for Your Project

What is 3-Axis CNC Machining? A Foundational Approach

3-axis CNC machining is one of the most common and widely used forms of computer-controlled manufacturing. It represents a fundamental and powerful method for producing a vast array of parts. In this process, the workpiece remains fixed in a single position while the cutting tool moves along three linear axes to cut and shape the material. Think of it as a highly precise, automated version of carving where the tool can only move up-and-down, left-and-right, and forward-and-backward relative to the stationary block of material.

How Does 3-Axis Machining Work?

The operation of a 3-axis machine is straightforward and is defined by its axes of motion. These axes correspond to the Cartesian coordinate system:

- X-axis: Left to right movement.

- Y-axis: Front to back movement.

- Z-axis: Up and down movement.

The CNC controller reads a computer-aided design (CAD) file that has been converted into G-code, a set of instructions that dictates the tool’s path. The spindle, holding the cutting tool, then executes these instructions, moving along the X, Y, and Z axes simultaneously to machine the part. Because the workpiece is stationary, only one side of the part can be machined at a time. To access other sides, the operator must manually stop the machine, unclamp the part, and re-fixture it in a new orientation. This process of multiple setups can introduce potential for error and increases overall production time for parts that are not simple.

Advantages and Limitations of 3-Axis Machining

The widespread use of 3-axis machining is due to its significant benefits for certain applications. Its primary advantage is its simplicity and cost-effectiveness. The machines themselves are less expensive to purchase and maintain, the programming is simpler and faster, and the setup for straightforward jobs is quick. This makes 3-axis machining the go-to choice for producing parts with relatively simple geometries, such as brackets, plates, housings, and components that require drilling, slotting, or facing operations on a single plane.

However, the process has notable limitations. The biggest drawback is its inability to machine complex curves, deep cavities with drafted walls, or undercuts in a single operation. Machining any feature that isn’t accessible from the top-down orientation requires a new setup. Each additional setup not only adds significant labor time but also introduces a risk of positional inaccuracy as the part is re-clamped. This can compromise the final tolerance and geometric relationship between features on different sides of the part.

What is 5-Axis CNC Machining? The Advanced Solution

5-axis CNC machining represents a significant leap forward in manufacturing capability. It builds upon the foundation of 3-axis machining by introducing two additional rotational axes. This allows for the simultaneous movement of the cutting tool and/or the workpiece, enabling the machining of incredibly complex geometries with unparalleled precision and efficiency. It is the technology behind some of the most advanced components in the aerospace, medical, and automotive industries.

How Does 5-Axis Machining Work?

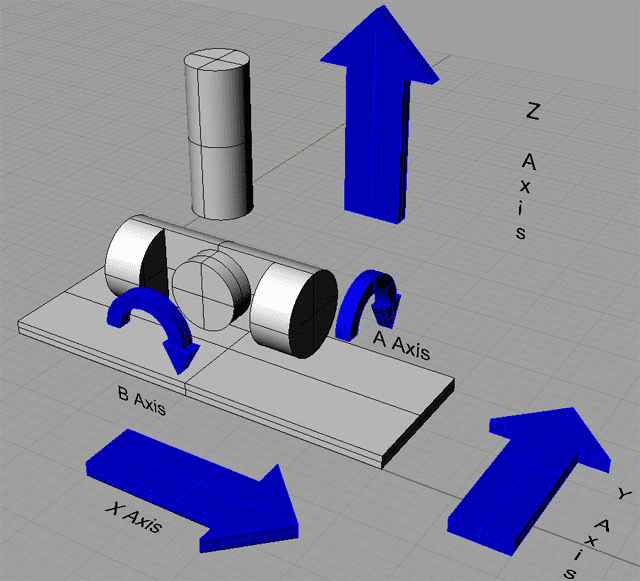

A 5-axis machine operates with the same three linear axes (X, Y, and Z) as a 3-axis machine, but adds two rotational axes to the mix. These rotational axes are typically designated as:

- A-axis: Rotation around the X-axis.

- B-axis: Rotation around the Y-axis.

- C-axis: Rotation around the Z-axis.

The specific combination of rotational axes (e.g., A and C, or B and C) depends on the machine’s configuration. In some machines, like a trunnion-style machine, the table holding the workpiece tilts and rotates (providing the two rotational axes). In others, the machine’s head rotates. This multi-axis movement allows the cutting tool to maintain an optimal orientation to the workpiece surface at all times. The ability to tilt the tool or the table means the machine can access five sides of a part in a single setup, drastically reducing the need for manual repositioning.

Distinguishing 3+2 Axis vs. Continuous 5-Axis

It’s important to understand the distinction between two types of 5-axis machining, as they offer different capabilities:

- 3+2 Axis Machining (Indexed or Positional 5-Axis): In this method, the machine uses its two rotational axes to lock the workpiece into a specific tilted position. Once the workpiece is fixed at this compound angle, the machine then performs 3-axis milling operations. It does not move the rotational axes during the cutting process. This is essentially a series of 3-axis operations performed at different angles without needing to re-fixture the part. It’s excellent for reducing setups and machining features on multiple faces.

- Continuous 5-Axis Machining (Simultaneous 5-Axis): This is the most advanced form, where the machine’s three linear axes and two rotational axes all move at the same time during the cutting process. This fluid, coordinated motion allows the machine to create complex, contoured surfaces like turbine blades, impellers, and organic shapes. It enables the use of shorter, more rigid tools, which can be run at higher speeds, resulting in superior surface finishes and reduced tool vibration.

Advantages and Limitations of 5-Axis Machining

The primary advantage of 5-axis machining is its ability to produce parts with extreme complexity in a single setup. This “done-in-one” approach dramatically reduces lead times, eliminates the risk of errors from multiple setups, and achieves tighter tolerances between features on different faces. It allows for better tool access to tight spaces and the use of shorter cutting tools, which increases tool life and allows for higher cutting speeds, resulting in a superior surface finish.

The main limitations are related to cost and complexity. 5-axis CNC machines are significantly more expensive than their 3-axis counterparts. The programming (CAM) software is more complex and requires highly skilled programmers and operators, which increases labor costs. The initial investment is substantial, making it less viable for simple parts or low-budget projects where its advanced capabilities are not required.

Head-to-Head Comparison: 3-Axis vs. 5-Axis

Choosing the right machining process requires a direct comparison of their core attributes. The following table breaks down the key differences between 3-axis and 5-axis CNC machining across several critical metrics.

| Feature | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

| Axes of Movement | 3 linear axes (X, Y, Z). Workpiece is stationary. | 3 linear axes (X, Y, Z) + 2 rotational axes (A, B, or C). |

| Part Complexity | Best for simple, prismatic parts, 2.5D geometries, drilling, and facing. | Ideal for complex contours, undercuts, and multi-faceted parts. |

| Number of Setups | Often requires multiple setups to access different sides of the part. | Can machine up to 5 sides of a part in a single setup. |

| Accuracy & Precision | Good, but accuracy can be lost between multiple setups. | Extremely high due to single-setup machining, eliminating re-fixturing errors. |

| Surface Finish | Good. Can be limited by tool length and angle of approach. | Superior. The tool can maintain a constant, optimal angle to the surface. |

| Cost | Lower initial machine cost, simpler programming, and lower hourly rates. | Higher machine cost, complex programming, and higher hourly rates. Can be more cost-effective for complex parts due to efficiency. |

| Lead Time | Faster for simple parts; slower for complex parts due to multiple setups. | Slower for simple parts due to programming overhead; much faster for complex parts. |

| Common Applications | Housings, brackets, plates, molds with simple cavities, general fabrication. | Aerospace components, medical implants, turbine blades, impellers, complex molds. |

How to Choose Between 3-Axis and 5-Axis Machining? Key Decision Factors

Selecting the appropriate machining process is not simply about choosing the one with the most axes; it’s a strategic decision based on a careful analysis of your project’s specific requirements. Answering the question “Which CNC machine is right for my part?” involves weighing several critical factors.

Part Geometry and Complexity

This is the most important factor. Take a hard look at your CAD model. Does the part consist mainly of flat surfaces, pockets, and holes on a single plane or a few orthogonal faces? If so, 3-axis machining is likely the most efficient and economical choice. If your part features complex curves, organic shapes, sweeping surfaces, deep cavities with angled walls, or features on multiple non-orthogonal faces (like an impeller or a bone implant), then 5-axis machining is almost certainly required to produce the part accurately and efficiently, if at all.

Budget and Cost Considerations

Your budget plays a huge role. 3-axis machining offers a significantly lower barrier to entry, with lower hourly rates and less expensive programming. For prototypes and simple parts, it’s the clear winner on cost. However, the cost calculation can be deceiving. If a complex part requires five different setups on a 3-axis machine, the accumulated labor and fixture costs might exceed the cost of machining it in a single setup on a 5-axis machine. Always evaluate the total project cost—not just the hourly rate. For complex parts, 5-axis can offer a lower piece-part cost despite its higher initial expense.

Required Accuracy and Surface Finish

For applications where precision is paramount, 5-axis often has the upper hand. The “done-in-one” approach of 5-axis machining eliminates tolerance stack-up errors that can occur when a part is manually re-fixtured multiple times in a 3-axis workflow. Furthermore, by continuously adjusting the tool’s angle, a 5-axis machine can use shorter, more rigid tools and maintain an optimal cutting position. This reduces tool deflection and chatter, leading to a demonstrably superior surface finish that may eliminate the need for secondary polishing operations.

Production Volume and Lead Time

How quickly do you need your parts, and how many do you need? For a one-off simple part, 3-axis is faster due to simpler programming. For high-volume production of complex parts, 5-axis machining’s ability to reduce cycle times by eliminating setups makes it much faster and more repeatable. A 5-axis machine can run “lights-out” (unattended) on complex jobs, dramatically increasing throughput and shortening overall lead times for a production run.

The Future is Complex: Why 5-Axis is Gaining Ground

While 3-axis machining remains a vital and cost-effective solution for a huge segment of the manufacturing market, the industry trend is undeniably moving towards greater complexity. Advances in generative design, lightweighting, and performance optimization are creating parts with more organic and intricate shapes than ever before. Industries like aerospace, medical, and high-performance automotive are pushing the boundaries of what is possible, and these designs often can only be realized through 5-axis machining. As the technology becomes more accessible and the software more intuitive, 5-axis machining is transitioning from a niche, specialized process to an essential tool for competitive, modern manufacturing.

Conclusion: Making the Right Choice for Your Project

The choice between 3-axis and 5-axis CNC machining is a matter of matching the right tool to the job. 3-axis machining is the economical and efficient workhorse for simpler, prismatic parts, offering speed and affordability where complexity is not a primary factor. 5-axis machining is the advanced, high-performance solution for intricate, multi-faceted parts, delivering unparalleled accuracy, superior surface finishes, and faster overall production times for complex geometries. By carefully evaluating your part’s complexity, budget, tolerance requirements, and lead time, you can confidently select the process that will deliver the best possible outcome for your manufacturing project.

3-axis vs 5-axis, CNC machining, 5-axis CNC, 3-axis machining, what is 5 axis machining, difference between 3 axis and 5 axis cnc machine, when to use 5-axis machining, 3+2 axis machining, continuous 5-axis machining, CNC machining cost, CNC part complexity, precision manufacturing, how to choose cnc machining