A vertical CNC machine, more formally known as a Vertical Machining Center (VMC), is a highly precise, computer-controlled manufacturing tool used for shaping solid materials like metal and plastic. Its defining characteristic is its vertically oriented spindle, which holds and rotates the cutting tool. The machine operates on a Cartesian coordinate system, moving the workpiece or the tool along the X, Y, and Z axes to perform operations such as milling, drilling, tapping, and boring with exceptional accuracy and repeatability. These machines are the backbone of modern workshops, essential for producing everything from simple brackets to complex aerospace components.

How Does a Vertical CNC Machine Work? From Digital Design to Physical Part

The magic of a VMC lies in its ability to translate a digital design into a tangible, high-precision object. This process is a symphony of software, electronics, and robust mechanics. It begins with an idea and ends with a perfectly machined part, following a clear, automated workflow.

The Digital Blueprint: CAD to CAM

Everything starts with a Computer-Aided Design (CAD) model. Engineers and designers create a 2D or 3D digital representation of the final part. This CAD file is the master blueprint. Once the design is finalized, it’s imported into Computer-Aided Manufacturing (CAM) software. The CAM software is where the manufacturing strategy is developed. The operator specifies the type of cutting tools to use, the spindle speeds, feed rates, and the precise path the tool will take to remove material—this is known as the toolpath.

The Language of the Machine: G-Code

After the operator defines the strategy in the CAM software, the program post-processes this information into a set of instructions the machine can understand. This machine-readable language is called G-code (and sometimes M-code for miscellaneous functions). G-code is a series of alphanumeric commands that tells the VMC’s controller exactly where to move, how fast to move, and when to turn the spindle and coolant on or off. For example, a line of G-code might instruct the machine to move the tool linearly to specific X, Y, and Z coordinates.

The Machining Process in Action

With the G-code loaded into the machine’s CNC controller, the physical process begins. The operator secures the raw material (the workpiece) onto the machine’s worktable. The machine is initialized, and the program is executed. The controller reads the G-code line by line, activating high-precision servo motors that drive the ballscrews, moving either the table (carrying the workpiece) along the X and Y axes or the spindle head along the Z-axis. The vertically oriented spindle spins the cutting tool at high speeds, and as it moves, it precisely shaves away material from the workpiece, following the programmed toolpaths until the final shape is achieved.

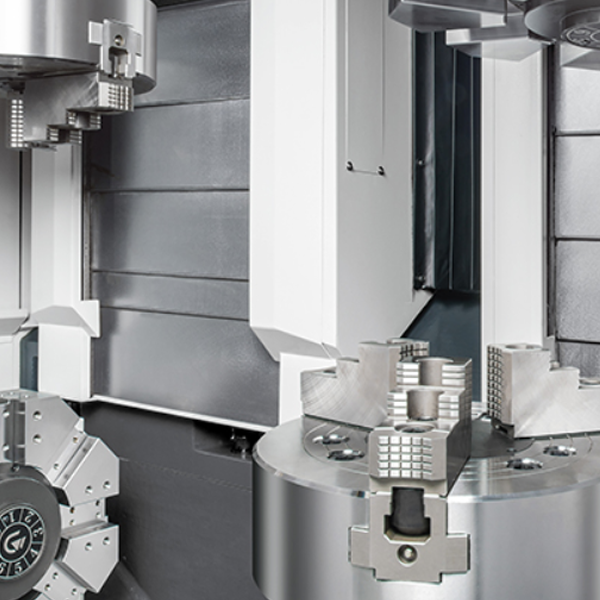

Unpacking the Anatomy: Core Components of a Vertical Machining Center

A VMC is a complex assembly of synergistic parts. Understanding these core components is crucial to appreciating its capabilities and the importance of build quality. As a manufacturer, we at Hirung know that the quality of each component directly impacts the machine’s overall precision, reliability, and lifespan.

| Component | Primary Function |

|---|---|

| Spindle | Holds, positions, and rotates the cutting tool. Its speed (RPM) and power (kW/hp) determine cutting performance. |

| Worktable | The flat, stable surface where the workpiece is mounted. It moves along the X and Y axes. |

| CNC Controller | The “brain” of the machine. It reads the G-code, processes the commands, and controls the motors and other systems. |

| Automatic Tool Changer (ATC) | A magazine that stores multiple cutting tools and automatically swaps them into the spindle as needed, enabling complex, uninterrupted operations. |

| Machine Frame & Column | The structural foundation of the machine. It supports all other components and provides the necessary rigidity to absorb cutting forces and vibrations. |

The Spindle: The Heart of the Operation

The spindle is arguably the most critical component. Its quality defines the machine’s cutting ability. It must be perfectly balanced to rotate at thousands of RPMs without vibration. There are two main types: belt-driven spindles, which are cost-effective and easy to maintain, and direct-drive spindles, which offer better performance at high speeds, reduced vibration, and improved thermal stability. The taper (e.g., BT40, CAT40) determines how the tool holders are seated, ensuring a rigid and concentric connection.

The Worktable: The Foundation for the Workpiece

The worktable is where the workpiece is securely clamped using fixtures, vises, or clamps. In a typical VMC, the table moves left-to-right (X-axis) and front-to-back (Y-axis). Its size dictates the maximum dimensions of the part that can be machined. A robust, precision-ground table is essential for ensuring the workpiece remains perfectly stable during aggressive cutting operations, which is fundamental to achieving tight tolerances.

The CNC Controller: The Brain of the Machine

The CNC controller is the sophisticated computer and interface that orchestrates the entire operation. It interprets the G-code and translates it into electrical signals sent to the machine’s servo motors. Modern controllers from brands like Fanuc, Siemens, and Mitsubishi offer user-friendly interfaces, advanced simulation features, and high-speed processing capabilities, which are essential for executing complex 3D toolpaths smoothly and accurately.

The Automatic Tool Changer (ATC): The Key to Efficiency

Modern manufacturing is about automation and efficiency. The Automatic Tool Changer (ATC) is a game-changer. It holds a carousel or chain of pre-set cutting tools. When the G-code calls for a tool change—for instance, switching from a roughing end mill to a finishing drill—the ATC mechanism quickly and precisely swaps the tools without any human intervention. This drastically reduces cycle times and enables “lights-out” manufacturing.

Why Choose a Vertical CNC Machine? Key Advantages and Considerations

VMCs are the most common type of CNC milling machine for a reason. Their design offers a unique blend of benefits that make them ideal for a wide range of applications, especially for small-to-medium-sized parts and job shops.

The Advantages of a VMC

- Simplicity and Ease of Use: The vertical setup is intuitive. Operators can easily see the cutting process, which simplifies setup, tool changes (if done manually), and monitoring. This visibility is excellent for training new machinists.

- Space Efficiency: VMCs typically have a smaller footprint compared to their horizontal counterparts. The vertical column design allows them to be more compact, making them a practical choice for workshops where floor space is at a premium.

- Cost-Effectiveness: Generally, VMCs are less expensive to purchase than HMCs of a similar size and capability. This lower barrier to entry makes them accessible to smaller businesses and startups.

- Ideal for Flat Work: Because gravity helps hold the workpiece down against the table, VMCs are perfect for jobs that involve machining on one side of a part, such as creating molds, dies, and plates.

Potential Limitations to Consider

While versatile, VMCs do have some limitations. Chip evacuation can be a challenge, as gravity can cause chips to accumulate on top of the workpiece, potentially leading to tool wear or a marred surface finish. This often requires the use of high-pressure coolant or air blasts to clear them away. Additionally, for high-volume production of multi-sided parts, a horizontal machine with a pallet changer might be more efficient.

The Axis Question: Understanding 3, 4, and 5-Axis VMCs

The “axis” count of a VMC refers to the number of directions in which the cutting tool or workpiece can move. This directly impacts the complexity of the parts that can be machined.

3-Axis VMCs: The Workhorse

A standard 3-axis VMC operates on the X, Y, and Z axes. The table moves in X and Y, and the spindle moves up and down in Z. This is perfect for 2.5D machining—operations on flat surfaces like drilling, tapping, profiling, and pocketing. They are the most common and versatile machines for a majority of milling tasks.

4-Axis VMCs: Adding Rotation

A 4-axis VMC adds a rotational axis (the A-axis) by incorporating a rotary table mounted on the main worktable. This allows the workpiece to be rotated, enabling machining on multiple sides of a part in a single setup. This is useful for creating parts with features on their sides, such as gears or components with holes drilled at angles around a cylinder.

5-Axis VMCs: For Ultimate Complexity

A 5-axis VMC adds a fifth axis of movement (the B or C axis), allowing the tool or the table to tilt and rotate simultaneously. This enables the machine to create incredibly complex geometries, such as turbine blades, medical implants, and aerodynamic automotive parts. 5-axis simultaneous machining allows the tool to maintain an optimal cutting position relative to the surface of the workpiece, resulting in better surface finishes and faster cycle times for complex contoured shapes.

Vertical vs. Horizontal CNC Machine (VMC vs. HMC): Which Is Right for Your Application?

One of the most common questions is whether to choose a Vertical Machining Center or a Horizontal Machining Center (HMC). The choice depends entirely on the type of work you do.

| Feature | Vertical Machining Center (VMC) | Horizontal Machining Center (HMC) |

|---|---|---|

| Spindle Orientation | Vertical | Horizontal |

| Best for… | Single-sided jobs, die/mold work, flat parts. | Multi-sided parts, tombstone fixturing, high-volume production. |

| Chip Evacuation | Challenging; chips can pile up on the part. | Excellent; gravity helps chips fall away from the part and tool. |

| Workpiece Size | Good for large, heavy, flat plates. | Better for cubic or tall parts. |

| Production Efficiency | Good, but often requires more setups for multi-sided parts. | Excellent, especially with integrated pallet changers for near-continuous machining. |

| Cost | Generally lower. | Generally higher. |

When to Use a VMC

You should choose a VMC for job shop work, prototyping, or when your primary work involves heavy, flat parts. Its ease of setup and visibility make it perfect for low-to-medium volume runs where jobs change frequently. If you’re machining molds, dies, or large plates that need work done on one primary face, a VMC is the most practical and cost-effective solution.

When an HMC Is the Better Choice

An HMC shines in high-production environments. By using a “tombstone” fixture on a rotary pallet, an HMC can hold dozens of parts at once, machining them on multiple faces without operator intervention. The superior chip evacuation makes it ideal for aggressive cutting in tough materials like titanium or steel, as chips fall away freely. If your goal is maximizing throughput and unmanned operation time, an HMC is the superior investment.

Real-World Impact: Applications of Vertical CNC Machines Across Industries

VMCs are ubiquitous in manufacturing. Their versatility allows them to produce critical components for nearly every major industry, showcasing their importance in the modern world.

- Aerospace: For machining structural components, brackets, and fittings from aluminum and titanium alloys that demand absolute precision and flawless finishes.

- Automotive: Used for prototyping and producing engine components, transmission parts, suspension elements, and creating the molds for plastic interior parts.

- Mold & Die: The core of the mold-making industry. VMCs are used to precisely carve complex cavities into hardened steel for injection molding, die casting, and forging.

- Medical: For manufacturing custom surgical implants (like knee and hip replacements), medical instruments, and prosthetic devices from materials like titanium and stainless steel.

- Electronics: Used to machine intricate heatsinks, custom enclosures for electronic devices, and frames for consumer electronics.

- Energy: Creating components for oil & gas exploration, as well as parts for wind turbines and other renewable energy systems.

Selecting the Perfect Vertical CNC Machine for Your Needs

Choosing the right VMC is a significant investment. As machine tool builders, we advise customers to look beyond the initial price and consider the factors that will ensure long-term performance and profitability.

Work Envelope and Machine Size

The “work envelope” refers to the maximum part size a machine can accommodate, defined by the X, Y, and Z axis travels. You must choose a machine that can handle your largest current parts, with some extra capacity for future growth. Also, consider the weight capacity of the table.

Spindle Speed and Power

What materials will you be cutting? Cutting soft materials like aluminum allows for very high spindle speeds (12,000-15,000 RPM or more) for fast material removal. Cutting hard materials like stainless steel or tool steel requires more torque and power at lower RPMs. Match the spindle specification to your primary application.

Machine Rigidity and Build Quality

A machine’s ability to produce accurate parts under heavy loads depends on its rigidity. Look for machines built with a heavy, one-piece cast iron frame. Cast iron is the preferred material for high-performance machine tools because it provides excellent vibration damping, thermal stability, and long-term geometric accuracy. High-quality linear guideways and precision-ground ballscrews are also critical for smooth, accurate motion.

Support and Service

A CNC machine is only as good as the support behind it. Ensure the manufacturer or distributor offers reliable technical support, readily available spare parts, and skilled service technicians. Downtime is incredibly expensive, so a strong service network is not a luxury—it’s a necessity. At Hirung, we pride ourselves on providing comprehensive after-sales service to ensure our customers’ machines are always running at peak performance.

Conclusion: The Enduring Power of the Vertical CNC Machine

The vertical CNC machine is more than just a tool; it’s a cornerstone of modern precision manufacturing. From its intuitive design and cost-effectiveness to its ability to be configured for highly complex 5-axis work, the VMC offers an unparalleled combination of flexibility and power. By understanding its core components, operational principles, and key advantages, businesses can leverage this technology to innovate, improve efficiency, and produce higher-quality parts. Whether you are a small job shop or a large-scale industrial manufacturer, the vertical machining center remains one of the most vital and valuable assets in the pursuit of manufacturing excellence.