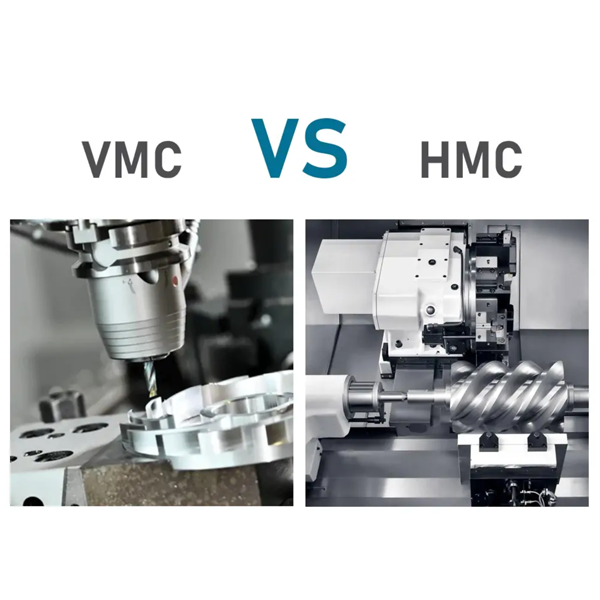

moving up and down to machine the top surface of a stationary workpiece, while an HMC features a horizontally oriented spindle that machines the sides of a workpiece mounted on a rotating tombstone or pallet. This fundamental design difference dictates everything from chip evacuation and workpiece setup to productivity and overall cost, making the choice between them a critical decision for any manufacturing operation.

What is a Vertical Machining Center (VMC)?

A Vertical Machining Center (VMC) is one of the most common types of CNC machine tools found in workshops around the world. As its name implies, its defining feature is a vertically aligned spindle. The cutting tool protrudes downwards from the tool holder, and the machine’s X and Y axes are controlled by the movement of the table the workpiece is fixtured to. This setup is highly intuitive and offers excellent visibility for the operator.

How a VMC Works

On a standard 3-axis VMC, the spindle moves along the Z-axis (up and down), while the table moves along the X-axis (left and right) and Y-axis (forward and backward). The workpiece is securely clamped onto the table, typically on its largest, flattest surface. Gravity works to its advantage, helping to hold the part firmly in place during machining. The operator has a clear, top-down view of the cutting action, which simplifies setup, monitoring, and manual interventions. VMCs are exceptionally versatile for tasks like drilling, tapping, and milling on a single face of a part in one setup.

Key Advantages of a VMC

-

- Cost-Effectiveness: VMCs generally have a lower initial purchase price compared to their horizontal counterparts, making them a more accessible entry point for startups and smaller job shops.

- Smaller Footprint: Their vertical design typically requires less floor space, a crucial consideration for workshops where space is at a premium.

* Simplicity and Ease of Use: The setup and programming for VMCs are often more straightforward. The excellent visibility allows operators to easily see what they are doing, simplifying programming, setup, and troubleshooting.

- Ideal for Large, Flat Parts: VMCs excel at machining large, heavy, or flat workpieces where the primary work is done on one side, such as mold bases, plates, and dies. Gravity aids in securing the part.

What is a Horizontal Machining Center (HMC)?

A Horizontal Machining Center (HMC) is a powerhouse of productivity, distinguished by its horizontally oriented spindle. Instead of the tool approaching the workpiece from above, it approaches from the side. The workpiece is typically mounted on a tombstone fixture, which is placed on a rotating B-axis table integrated into the machine. This design fundamentally changes the approach to machining and unlocks significant efficiency gains.

How an HMC Works

In an HMC, the spindle holds the tool horizontally, moving along the Z-axis (in and out). The column provides X-axis (side-to-side) and Y-axis (up and down) motion. The key feature is the rotary table (B-axis) that the workpiece is mounted on. This allows the machine to rotate the part and present multiple faces to the spindle without requiring a new setup. Most HMCs also come standard with an Automatic Pallet Changer (APC), which swaps a completed pallet (with finished parts) for a new pallet (with raw stock) while the machine is still cutting, virtually eliminating setup downtime.

Key Advantages of an HMC

- Superior Productivity: With multi-sided machining on a tombstone and pallet changers, HMCs can achieve spindle utilization rates of 85% or higher, compared to a typical 25% for a VMC. This makes them ideal for high-volume or recurring production runs.

- Excellent Chip Evacuation: Gravity becomes an asset for chip control. As the machine cuts, chips naturally fall away from the workpiece and into the chip conveyor below. This prevents chip recutting, improves surface finish, and extends tool life.

- Enhanced Rigidity and Accuracy: HMCs are often built with a more robust and rigid construction to handle aggressive cutting forces. The horizontal design and superb chip management contribute to higher thermal stability and repeatable accuracy.

- Multi-Part Setup: A tombstone fixture allows multiple parts to be set up at once, drastically reducing the time spent on loading/unloading and maximizing the machine’s cycle time.

Detailed Comparison: VMC vs. HMC Head-to-Head

Choosing between a VMC and an HMC requires a deep understanding of how their core differences impact your specific applications and business goals. Let’s break down the comparison across several critical factors.

Spindle Orientation and Gravity’s Role

This is the most fundamental difference. On a VMC, the vertical spindle works with gravity to hold the workpiece, which is excellent for heavy parts. However, gravity works against it for chip removal, as chips can pile up in pockets and require coolant floods or air blasts to clear. On an HMC, the horizontal spindle means gravity is a powerful ally in chip evacuation. Chips fall away cleanly, preventing issues like recutting, which can damage the tool and the part’s surface finish.

Workpiece Size, Weight, and Setup

A VMC is often the better choice for very large, heavy, and cumbersome parts, like large mold plates, that can be laid flat on the machine table. The setup is straightforward. A HMC excels with cube-shaped parts or parts that require machining on multiple faces. By mounting several parts on a tombstone fixture, an operator can prepare a full pallet of work while the machine is running, a process known as “lights-out” or unattended manufacturing. This makes HMCs the champions of production machining.

Chip Management and Its Impact

Effective chip management is not just about cleanliness; it’s about quality and tool life. The superior chip evacuation of an HMC leads to better surface finishes because there’s no risk of the tool recutting fallen chips. It also significantly extends the life of cutting tools, reducing operational costs over time. While VMCs have effective coolant systems, deep pocketing or complex contours can still present chip-clearing challenges that require careful programming and monitoring.

Productivity and Automation Potential

When it comes to pure throughput, the HMC almost always wins. The combination of a pallet changer and a tombstone fixture that presents 4 or more sides of a part (or multiple parts) to the spindle means the machine cuts almost continuously. A VMC, by contrast, typically requires the machine to be stopped for every part changeover and for each time the part needs to be re-fixtured to access another side. While VMCs can be automated with robots, the out-of-the-box productivity of an HMC is inherently higher.

Precision, Rigidity, and Surface Finish

While high-quality VMCs deliver excellent precision, HMCs often have a slight edge in applications demanding the utmost accuracy and finish. This is due to a combination of factors: they are generally engineered with greater rigidity to handle more aggressive cutting, and their superior chip management prevents imperfections caused by recutting. The reduction in setups also eliminates the potential for work-holding errors that can occur each time a part is moved on a VMC.

Machine Footprint and Operator Visibility

Here, the VMC has a clear advantage. Its vertical orientation results in a more compact machine that takes up less valuable floor space. The open design also gives the operator a direct, unobscured view of the cutting process, which can be beneficial for one-off jobs, prototyping, and training. HMCs are larger, more enclosed machines, and their pallet-changing systems require additional space.

Initial Investment vs. Total Cost of Ownership

The upfront capital investment for a VMC is significantly lower than for an HMC of a comparable work envelope. This makes it an attractive option for businesses with limited budgets. However, it’s crucial to consider the Total Cost of Ownership (TCO) and Return on Investment (ROI). An HMC, despite its higher initial cost, can often produce three to five times the output of a VMC. For high-volume production, the HMC’s productivity can lead to a lower cost-per-part and a much faster ROI, making it the more profitable long-term investment.

Quick Comparison Table: VMC vs. HMC

| Feature | Vertical Machining Center (VMC) | Horizontal Machining Center (HMC) |

|---|---|---|

| Spindle Orientation | Vertical (Up/Down) | Horizontal (In/Out) |

| Productivity | Good; ideal for single-setup jobs and low-to-mid volume. | Excellent; designed for high-volume, multi-side machining. |

| Chip Evacuation | Fair; chips can pool and require high-pressure coolant. | Excellent; gravity assists in clearing chips from the work area. |

| Workpiece Setup | Simpler, one-sided setup. Good for large, flat parts. | More complex; uses tombstone fixtures for multi-part, multi-side access. |

| Automation | Can be added (e.g., robotic tending). | Often includes integrated pallet changers for near-continuous operation. |

| Footprint | Smaller, more compact. | Larger, requires more floor space. |

| Initial Cost | Lower | Higher |

| Best For | Prototyping, small-to-medium runs, large/heavy plates, mold making. | High-volume production, recurring jobs, complex parts needing multi-side work. |

Which Machine Should You Choose? Key Questions to Ask

The “VMC vs HMC” debate doesn’t have a single winner; it has the right choice for your specific needs. By analyzing your production requirements, you can make an informed decision that boosts your shop’s efficiency and profitability.

What is your typical part complexity and volume?

If your work consists mainly of one-off prototypes, repair work, or low-volume runs on parts that only require machining on one or two faces, a VMC is likely the most practical and cost-effective solution. If you are running hundreds or thousands of identical parts, or complex parts that require access to three or more sides, the productivity gains from an HMC will quickly justify the investment.

What are your budget and floorspace constraints?

A frank assessment of your available capital and shop floor area is essential. If the budget is tight or space is limited, a VMC is the logical starting point. Its affordability and smaller footprint make it a workhorse for a huge range of shops. However, if you have the capital and space, it’s vital to calculate the potential ROI of an HMC. Don’t let the initial price tag deter you from what could be a far more profitable long-term solution.

What are your long-term production goals?

Where do you see your business in five years? If you plan to take on high-volume contracts from industries like automotive or aerospace, investing in an HMC from the start could be a strategic move that positions you for growth. If your business model is built around high-mix, low-volume flexibility and quick turnarounds, building a cell of versatile VMCs might be the better path.

Hirung’s Expertise in VMC and HMC Solutions

Making the right choice in CNC technology is fundamental to your success. At Hirung, we don’t just sell machines; we provide intelligent manufacturing solutions. With years of dedicated research, development, and manufacturing experience, we have engineered a full lineup of both high-precision Vertical Machining Centers and high-productivity Horizontal Machining Centers. Our experts understand the nuances that separate these two powerful platforms. We can help you analyze your parts, production goals, and budget to recommend the machine that will deliver the best performance and highest return on investment for your specific application.

Whether you need the versatility of our comprehensive range of Vertical Machining Centers or the unparalleled throughput of our robust Horizontal Machining Centers, Hirung has the technology and expertise to elevate your production capabilities.

Conclusion: Making the Intelligent Choice for Your Manufacturing Needs

In summary, the choice between a VMC and an HMC is not about which machine is “better,” but which is better suited to your specific work. The VMC is the versatile, accessible, and user-friendly choice, perfect for a wide range of applications, especially those involving single-sided work or low-volume runs. The HMC is the undisputed champion of productivity, an investment in speed and automation designed for high-volume, multi-sided, and unattended manufacturing. By carefully evaluating your parts, processes, and business goals, you can select the machine that will serve as a cornerstone of your shop’s profitability for years to come. When you are ready to explore your options, contact a Hirung CNC expert today to find the perfect fit.

Frequently Asked Questions (FAQ)

Is an HMC more accurate than a VMC?

Generally, an HMC can achieve slightly higher and more consistent accuracy over long production runs. This is due to its typically more rigid construction, better thermal stability from isolated heat sources, and superior chip control, which prevents artifacts from recutting. The reduced number of setups also minimizes the risk of positioning errors.

Why are HMCs so much more expensive than VMCs?

HMCs have a higher cost due to several factors: they are typically built with heaver, more rigid castings; they include a complex and precise rotary table (B-axis) as standard; and most come equipped with an Automatic Pallet Changer (APC). These features, which drive their incredible productivity, also add significantly to the machine’s complexity and manufacturing cost.

Can a VMC have 4 or 5 axes?

Yes. A VMC can be equipped with a 4th-axis rotary table (either an A or B axis) or a 5th-axis trunnion table (A and C axes) to enable multi-sided machining. This adds versatility but can reduce the work envelope and doesn’t offer the same seamless productivity as an integrated HMC with a pallet changer.

What is a tombstone on an HMC?

A tombstone is a large, typically four-sided fixturing block that is mounted on the HMC’s pallet. It allows an operator to mount multiple workpieces—or a single workpiece for access to multiple sides—at once. The HMC then rotates the tombstone via its B-axis to present each face to the spindle for machining, all within a single program cycle.