Achieving zero-defect machining for complex parts with extreme tolerances requires a synergy of mechanical rigidity, thermal stability, and advanced control systems. High-Precision VMCs, such as those engineered by HIRUNG, address this by integrating robust machine structures, high-performance spindles, and intelligent thermal compensation to ensure micron-level accuracy and repeatability, even during demanding, continuous operation.

What Defines Extreme Tolerances in Metal Machining?

In the world of manufacturing, “tolerance” refers to the permissible limit of variation in a physical dimension. While standard machining operates within a comfortable range, extreme tolerances push the boundaries of what is possible, often demanding accuracy measured in single-digit microns (μm). A micron is one-thousandth of a millimeter. Holding a tolerance of ±5 μm means the final part dimension cannot deviate by more than the width of a spider’s silk thread.

These stringent requirements are not for aesthetic purposes; they are fundamental to the performance and safety of the final product. In industries like aerospace, the precise fit between turbine components directly impacts fuel efficiency and operational integrity. In the medical field, the surface finish and dimensional accuracy of a surgical implant determine its biocompatibility and longevity. Achieving this level of precision consistently—part after part—is the hallmark of zero-defect machining.

The Core Challenges of Machining Complex Geometries

Machining intricate metal parts to tight tolerances presents a formidable set of obstacles. The very act of cutting metal induces stresses, heat, and vibration, all of which are enemies of precision. For complex geometries with deep pockets, thin walls, and contoured surfaces, these challenges are magnified. Tool deflection, where the cutting tool bends minutely under load, can lead to dimensional inaccuracies. Chatter, a high-frequency vibration between the tool and workpiece, ruins surface finish and can cause premature tool failure.

Furthermore, the material itself plays a significant role. Hard-to-machine superalloys like Inconel or titanium, common in demanding applications, generate immense heat and cutting forces. This not only accelerates tool wear but also causes thermal expansion in the workpiece, making it difficult to maintain dimensional stability. Each axis of movement, tool change, and operational variable introduces a potential for error, which can accumulate to push a part outside its required tolerance band.

How Does Machine Rigidity Form the Bedrock of Precision?

The foundation for any high-precision machining operation is the machine’s structural integrity, or rigidity. A machine that flexes or vibrates under load cannot possibly hold tight tolerances. HIRUNG VMCs are engineered from the ground up with this principle in mind. The machine base, column, and saddle are constructed from high-grade Meehanite cast iron, which is renowned for its excellent vibration-damping characteristics and long-term stability.

This robust construction is further enhanced by design. A wide stance, heavy ribbing, and oversized components create a structure that effectively absorbs and dissipates cutting forces rather than deflecting. HIRUNG utilizes Finite Element Analysis (FEA) during the design phase to simulate operational stresses and optimize the machine’s structure, ensuring maximum static and dynamic rigidity. Whether employing heavy-duty box ways for maximum damping in heavy cutting or high-speed linear guideways for rapid acceleration, the core architecture is built to provide an unyieldingly stable platform for the cutting tool.

The Critical Role of High-Performance Spindles

The spindle is the heart of a Vertical Machining Center, responsible for rotating the cutting tool at high speeds with exceptional accuracy. For extreme precision work, any flaw in the spindle’s performance translates directly into part defects. Key factors include spindle runout (the rotational wobble of the tool), thermal growth, and balance. Excessive runout leads to inconsistent tool engagement, resulting in poor surface finish and dimensional errors.

HIRUNG equips its VMCs with high-performance spindles designed to minimize these effects. Direct-drive or built-in motor spindles, featured in series like the HV high-speed machines, eliminate belts and gears that can introduce vibration and backlash. These spindles are meticulously balanced for high-RPM operation and feature advanced ceramic bearings to reduce friction and heat generation. This ensures that the tool tip remains precisely on its programmed path, carving out features with exceptional accuracy and creating superior surface finishes.

Why is Thermal Stability Non-Negotiable for Zero-Defect Output?

Heat is the silent enemy of precision machining. Generated by the spindle motor, axis movements, and the cutting process itself, thermal energy causes machine components and the workpiece to expand. Even a few degrees of temperature change can cause the machine frame to distort by several microns, throwing off the part’s accuracy. For long-running jobs or when striving for zero-defect production, managing this thermal growth is not optional—it is essential.

HIRUNG VMCs incorporate a multi-faceted approach to thermal stability. This begins with isolating heat sources and actively cooling critical components. A dedicated spindle cooling system circulates chilled fluid around the spindle housing to whisk away heat and prevent thermal expansion. Furthermore, intelligent thermal compensation systems use sensors placed at key points on the machine structure. These sensors feed real-time temperature data back to the CNC control, which then applies minute, calculated adjustments to the axis positions to counteract any thermal drift. This closed-loop system ensures consistent accuracy from the first part to the last, regardless of ambient temperature changes or machine operating time.

| Source of Thermal Error | Impact on Machining | HIRUNG’s Mitigation Strategy |

| Spindle Motor | Causes spindle growth (Z-axis error), affects tool height. | Spindle Chiller System: Actively circulates coolant to maintain a constant spindle temperature. |

| Axis Drive Motors & Ball Screws | Causes ball screw expansion, leading to positioning errors (X/Y/Z axes). | Pre-tensioned Ball Screws: Minimizes heat generation and expansion; high-efficiency motors reduce waste heat. |

| Cutting Process | Heats the workpiece, causing it to expand and leading to inaccurate dimensions post-cooling. | High-Pressure Coolant: Efficiently flushes heat and chips from the cutting zone. |

| Ambient Environment | Changes in shop temperature can cause the entire machine frame to expand or contract. | Intelligent Thermal Compensation: Multi-point sensors and software algorithms adjust axis positions in real-time to counteract frame distortion. |

Unlocking Precision Through Advanced CNC Controls and Drives

A rigid machine is only as good as the control system that guides it. To machine complex surfaces and maintain tight tolerances, the CNC control must process vast amounts of code quickly and translate it into smooth, precise machine movements. Modern controls from industry leaders like FANUC and Siemens, utilized by HIRUNG, feature high-speed processing and advanced look-ahead functions. This allows the control to anticipate upcoming changes in the toolpath, enabling smoother acceleration and deceleration without jerking motions that could mar the part surface.

This processing power is paired with high-resolution encoders and responsive servo drives on each axis. The system constantly monitors the machine’s actual position and compares it to the commanded position thousands of times per second, making micro-adjustments to ensure the toolpath is followed with sub-micron precision. This capability is crucial for 3D contouring and high-speed machining, where path accuracy directly determines the final form and fit of the component.

What is the Impact of Axis Kinematics and Ball Screw Accuracy?

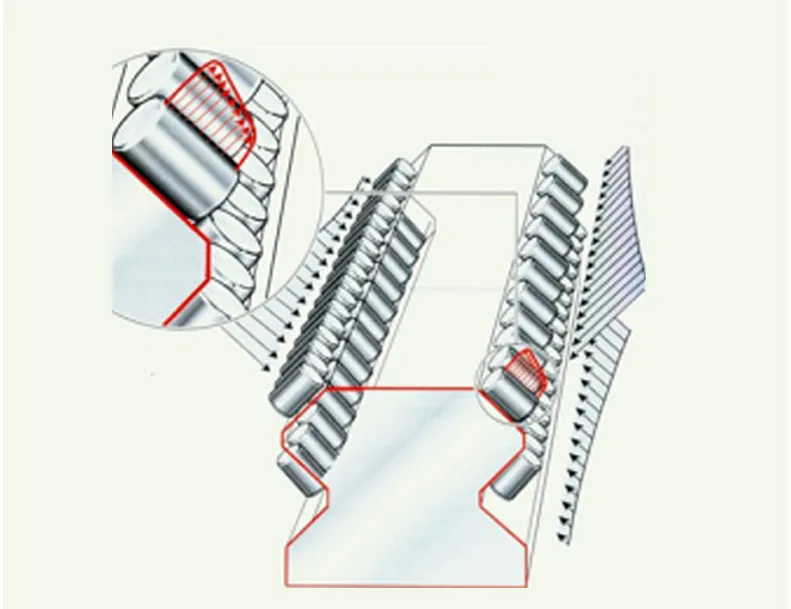

The system responsible for moving the machine’s table and spindle—the axis kinematics—must be flawlessly accurate. The primary components governing this are the linear guideways and ball screws. HIRUNG VMCs use high-precision, low-friction linear guideways that allow for rapid, smooth movement with minimal stick-slip effect, a phenomenon that can cause jittery motion and positioning errors.

Even more critical are the ball screws, which convert the rotary motion of the servo motors into linear movement. HIRUNG utilizes high-grade, C3 class ground ball screws to ensure exceptional lead accuracy. To eliminate backlash—the tiny amount of play that can occur when an axis reverses direction—these ball screws are double-nutted and pre-tensioned. After assembly, the positioning accuracy of every machine is verified and calibrated along the entire length of each axis using a laser interferometer, guaranteeing that the machine’s commanded position is its true physical position.

Integrating In-Process Metrology for Proactive Quality Control

The path to zero-defect machining involves a shift from reactive, post-process inspection to proactive, in-process control. Instead of waiting until a part is finished to find out if it is good, modern VMCs use integrated probing to verify quality during the machining cycle. HIRUNG VMCs can be equipped with high-precision touch-trigger probes for this purpose.

These probes can be used automatically for several critical tasks. Before cutting, a probe can accurately locate the workpiece, establishing a precise work offset. It can also measure the length and diameter of a tool after a tool change. Most importantly, in-process metrology allows the machine to measure a critical feature mid-cycle. If the measurement reveals a deviation due to tool wear or slight thermal changes, the CNC control can automatically update the tool offset and re-machine the feature to bring it perfectly into tolerance. This proactive correction is a cornerstone of achieving error-free production runs.

The Synergy of Tooling and Workholding in Precision Machining

A state-of-the-art VMC still requires a high-quality ecosystem of tooling and workholding to perform at its peak. The connection between the spindle and the cutting tool, managed by the tool holder, is a critical link. Low-quality holders can introduce runout, defeating the precision of the spindle. That is why systems using dual-contact holders (like BBT or HSK) are preferred, as they provide both taper and face contact with the spindle, ensuring superior rigidity and positional accuracy.

Similarly, the workpiece must be held with absolute security. Any movement or vibration of the part during machining will result in an immediate loss of accuracy. Robust and precise workholding, such as hydraulic vises or custom fixtures, is essential. The stability of the entire system—from the machine frame through the spindle, tool holder, tool, and workholding—must be treated as a single, integrated unit to successfully machine parts to extreme tolerances.

Which Industries Rely on HIRUNG for Mission-Critical Components?

The capabilities of HIRUNG VMCs to deliver uncompromising precision and reliability make them trusted assets in industries where failure is not an option. These sectors depend on the ability to machine complex parts from challenging materials while holding the tightest tolerances, a task for which HIRUNG machines are expressly designed.

In the aerospace industry, HIRUNG VMCs are used to produce structural components, engine parts, and landing gear assemblies from materials like titanium and aluminum alloys. The geometric complexity and critical safety requirements of these parts demand the rigidity and thermal stability that our machines provide. For the medical sector, our VMCs manufacture custom orthopedic implants, surgical instruments, and dental prosthetics, where both micron-level accuracy and impeccable surface finishes are required for biocompatibility and patient safety. In the mold and die industry, the ability to create complex cavities and cores with mirror-like surfaces and precise parting lines directly impacts the quality of the final molded product, making the precision of HIRUNG machines an invaluable asset.